| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Briquetting Machine |

|---|---|

| Brand Name: | Xrido |

| Model Number: | Customizable |

| Certification: | CE ISO TUV |

| Payment Terms: | Negotiable |

| Delivery Time: | 2-30 Working Days |

| place of origin: | Henan, China |

| type: | Refuse Collector |

| warranty: | 1 Year |

| material: | Export Wooden Packing |

| machinery test report: | Provided |

| video outgoing-inspection: | Provided |

| core components: | Pressure vessel, motor, Bearing, Gear, PLC, Pump, Engine |

| weight (kg): | 800 |

| Power: | Custom |

| Product name: | Refuse Derived Fuel RDF Briquette Press Machine |

| Application: | Recycling and Utilization of Waste |

| Suitable material: | Hard Wood Briquette |

| After Warranty Service: | Field Maintenance |

| Advantage: | Easy Operation High Efficiency |

| Briquette size: | 8-75mm |

| Usage: | Make Fuel Briquettes |

| Production Capacity: | 100% |

| Voltage: | Country Voltage |

| Company Info. |

| Henan Xrido Environmetal Protection Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

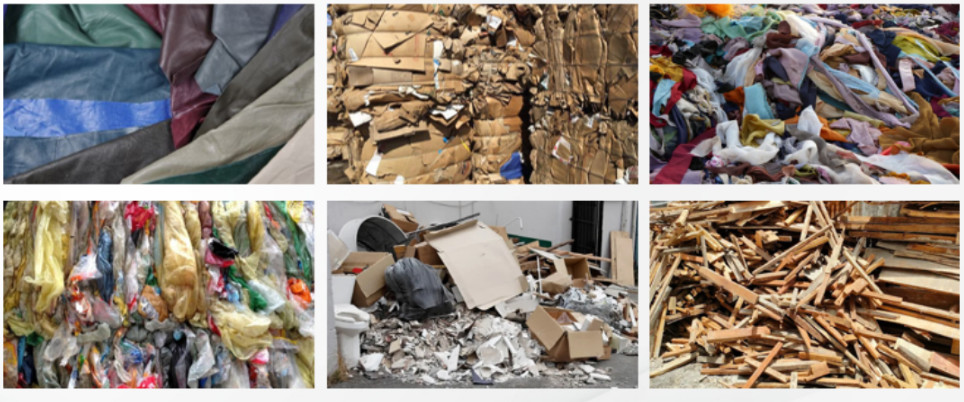

What kind of equipment is needed to convert solid waste into high calorific value alternative fuel? XRIDO Group is a solid waste pretreatment equipment provider with more than 10 years of experience in the solid waste pretreatment equipment industry. Focusing on the three major mixed domestic waste/other waste pretreatment goals of "recyclable sorting", "organic matter extraction", and "combustible preparation of RDF/SRF", it provides a complete set of mature and reliable alternative fuel (RDF/SRF) preparation systems and equipment. At present, there are project cases in domestic waste transfer stations, renewable resource utilization centers, and cement manufacturing industries in various regions.

Advantages of RDF briquetting machine

Resource benefits: Convert low calorific value garbage into

standard fuel (calorific value 16-25MJ/kg), replace fossil energy

such as coal, and reduce landfill volume by more than 30%.

Environmental friendliness: No binder is required during the

compression process, sulfur oxide emissions during combustion are

50% lower than coal, and ash can be used as raw materials for

building materials.

Economic efficiency: The volume of fuel is reduced by 3-5 times

after molding, reducing transportation and storage costs, and can

be adapted to various industrial facilities such as cement kilns

and power generation boilers.

Technical adaptability: The modular design can handle a variety of

raw materials such as mixed garbage and industrial waste, and the

intelligent control system can achieve precise adjustment of

moisture content (≤15%) and density.

| Model | XRD600 | XRD800 |

| Capacity(t/h) | 2.5-3 | 4-4.5 |

| Motor power(kw) | 180(90*2) | 220(110*2) |

| Ring mold size(mm) | ∅608 | ∅768 |

| Press roller quantity(pcs) | 2 | |

| Transmission method | Asynchronous motor V-belt + gear | Water-cooled synchronous motor Timing belt + gear |

| Feeding type | Horizontal screw + forced feeding | |

| Machine size(m) | 3.2*2.2*2.1 | 3.2*2.3*2.1 |

| Weight(kgs) | 8480 | 13900 |

Providing one-stop Solution

The company's main products include double-axis shredders, metal crushers, solid waste disposal equipment and renewable resource equipment to meet the needs of different customers. By providing a one-stop solution, XRIDO Group can helps customers solve various solid waste treatment problems.

Waste to Biomass/RDF/SRF/TDF Briquette System:

The solid waste disposal system can be customized according to the actual materials.

|

|

| MSW to RDF briquette Plant | Industrial Waste to RDF briquette Plant |

|

|

| Biomass pellet/briquette Plant | Waste Tire Disposal System |

|