ERNiCrMo-14 Nickel Welding Wire with 690 MPa Tensile Strength for Nickel Base Alloy 686 and Melting Point 1338-1380°C

|

A5.14 ERNiCrMo 14 1.6mm Welding Rod For Sale Nickel Based Welding Wire DLX alloy offering ErNiCrMo-14, which is one of the nickel based welding wire. AWS A5.14 ErNiCrMo-14 For welding Nickel base alloy 686. This consumable match the 686 nickel base alloy and for overmatch nickel base alloy such as alloy 59, C22, C276 and 625. It is also used for dissimilar welds......

Changzhou DLX Alloy Co., Ltd.

|

AWS A5.14 ErNiCu 7 Monel 400 Nickel Welding Wire NO5500

|

...overlaying steel after first applying Layer of 610 nickel. It is used for joining base materials such as UNS number NO4400, NO4405, and NO5500. This alloy can be used for dissimilar welding applications using various nickel-copper alloys to nickel 200 and...

Huona (Shanghai) New Material Co., Ltd.

|

AWS A5.14 UNS N06686 Ernicrmo-3 Inconel Nickel Welding Wire In Oil Pipeline Welding

|

...Nickel Welding Wire ErNiCrMo-3 is a common nickel-based welding wire commonly used in welding applications in high temperature and corrosive environments. The following is a product introduction to ErNiCrMo-3 welding wire: 1. Chemical composition: The main chemical components of ErNiCrMo-3 welding wire include nickel......

Changzhou Victory Technology Co., Ltd

|

ERNi-1 Special Nickel Welding Wire Super Alloy Excellent Welding Process Performance For Marine Equipment

|

...Wires Super Alloy Excellent Welding Process Performance For Marine Equipment ERNi-1 is a nickel-based welding wire classified under AWS A5.14 as ERNi-1. It is primarily used for welding commercially pure nickel (UNS N02200/N02201) and offers excellent corrosion resistance in reducing and neutral environments. The wire features high nickel......

Jiangyin Chengxin Alloy Material Co., Ltd ,

|

Welding Wire Aws 5.14 Nickel Alloy Wire Ernicrmo-4 For Nickel Base Alloys

|

... corrosion cracking and pitting and crevice corrosion. Common Names: Oxford Alloy® C-276 FM C-276 Techalloy 276 Standard: AWS A5.14, ERNiCrMo-4/...

Shanghai Tankii Alloy Material Co.,Ltd

|

ERNiCrMo 3 Nickel Weld Wires Dia 1.2mm ERNiCrFe-7 Inconel Welding Wire

|

Nickel Weld Wires Dia 1.2mm AWS A5.14 ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCu-7,ERNiCu-7 Basic Info. Model NO. Nickel Welding Wire Chemical Composition Ernicr 3/Ernicr-4 MOQ 1kg Surface Bright Density 8.908 G/Cm³ Resistance......

HENAN HUAMAO METAl MATERIALS CO ,LTD

|

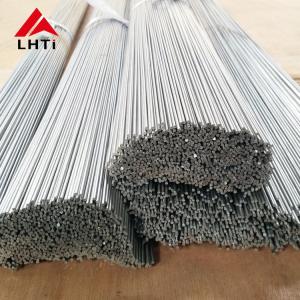

AWS A5.16 Titanium welding wire ErTi-2 Straight Welding Wire

|

...A5.16 Titanium Welding Wire is specifically designed for the welding of titanium and titanium alloys. It offers excellent weldability, corrosion resistance, and mechanical properties, making it suitable for demanding applications in aerospace, chemical processing, marine, and medical industries. This wire is available in multiple grades, diameters, and finishes to meet various welding......

Baoji City Changsheng Titanium Co.,Ltd

|

ERTI 5 2.4mm Titanium Straight Wire Aws A5.16 Titanium Welding Wire

|

...Wire Aws A5.16 Titanium welding wire has excellent welding process performance, beautiful weld formation, and its welded metals have excellent comprehensive mechanical properties. Mainly used for welding of titanium-based alloys. Radiographic inspection requirements for weld metal inspection: Grade Ⅰ Titanium wire specifications A. Titanium wire specifications: φ0.8-φ6.0mm B. Spectacle titanium wire...

Baoji Lihua Nonferrous Metals Co., Ltd.

|

NO6022 Nickel Welding Wire Light Rod Nickel Chromium Molybdenum Alloy

|

KX NO6022 Welding Wire Light Rod on Nickel Based Welding Wire Alloy Product Description and Application NO6022 is also known as N10276 SNi6276, NiCr15Mo16Fe6W4 NO6022 is 57Ni16Cr15.5Mo nickel-base welding wire for nickel-chromium-molybdenum series. The ......

Danyang Kaixin Alloy Material Co., Ltd.

|

ER70S-6 Gas Shielded Welding Wire / AWS A5.18 70s6 Welding Wire

|

...Welding Wire / AWS A5.18 70s6 Welding Wire Product Description ER70S-6 is a gas shielded copper plated welding wire that can be protected by CO2 or argon rich gas during welding. The wire feeding is stable, the weld formation is beautiful, and the welding smoke and splash are small. The weld seam has high tensile and low-temperature impact resistance. Suitable for all position welding......

Hainan Chenxiang New Material Technology Co., Ltd.

|