| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Sheet Metal Welding Parts |

|---|---|

| MOQ: | 1PC |

| Price: | Negotiable |

| Payment Terms: | T/T,L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 200000Pcs/ Month |

| Delivery Time: | 10-15 working days |

| Packaging Details: | Carton, wooden box, or as customer's request |

| Brand Name: | CRIDA |

| Model Number: | Customized |

| Certification: | ISO 9001:2015 |

| Place of Origin: | Guangdong, China |

| Surface Finish: | Powder Coated, Sand Blasted, Passivate, Anodizing |

| Tolerance: | +/- 0.1mm or special requirements |

| Color: | Customized Color |

| Process: | Sheet metal processing, Bending, Welding |

| Part Name: | Sheet Metal Fabrication Service |

| Application: | Auto /Moto Parts, Machinery Parts, Lighting Components, Hardware Accessories, Electric Motor Products |

| size: | Custom size |

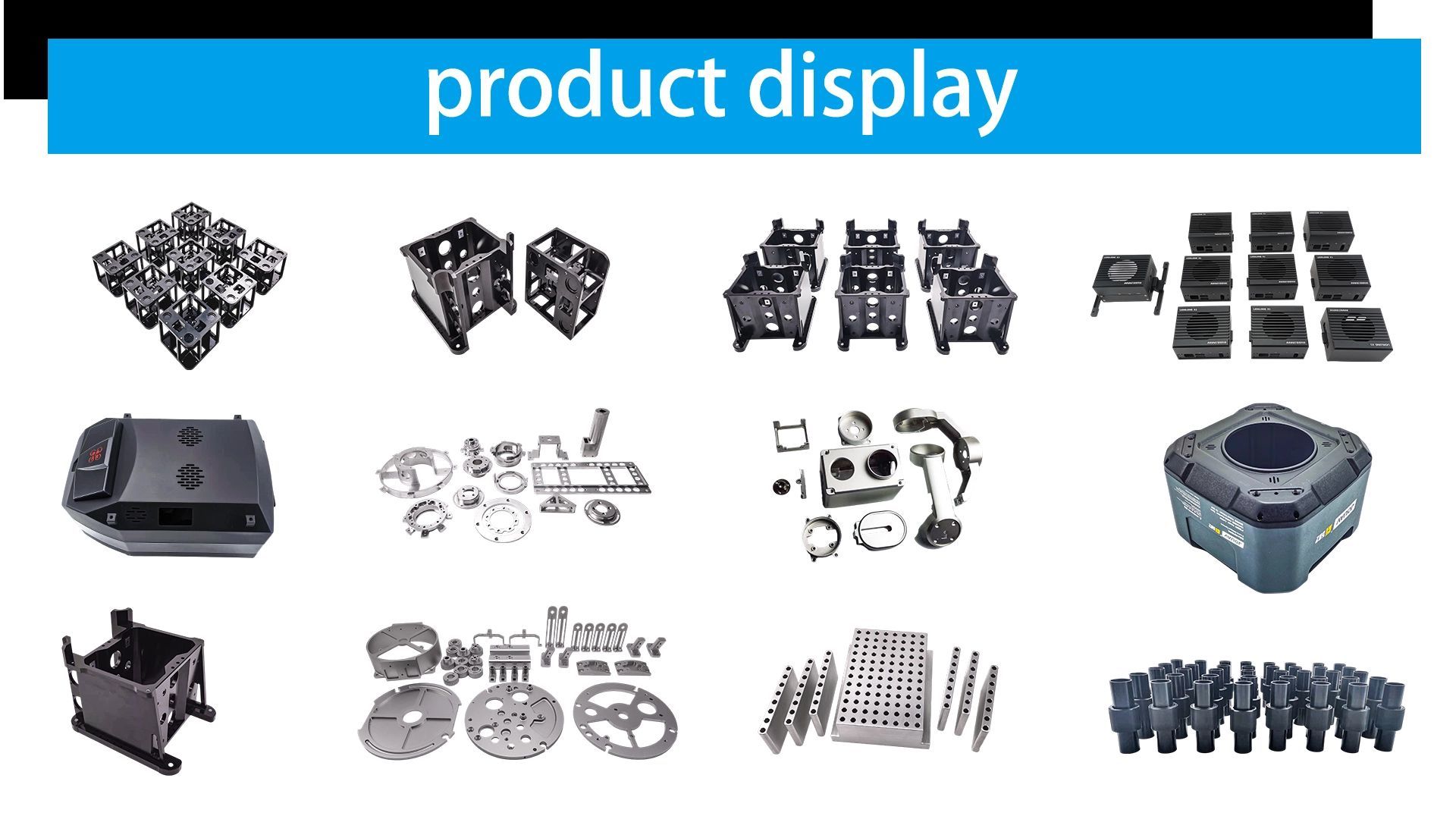

| Highlight: | Customized Sheet Metal Manufacturing Services, Precision CNC Parts Machined , Custom CNC Sheet Steel Galvanized Stamping Bending Sheet Metal Weldling Parts |

| Drawing Format: | STP, IGS, CAD, PDF, STEP, X_T |

| QC Control: | 100% Inspection Before Shipment |

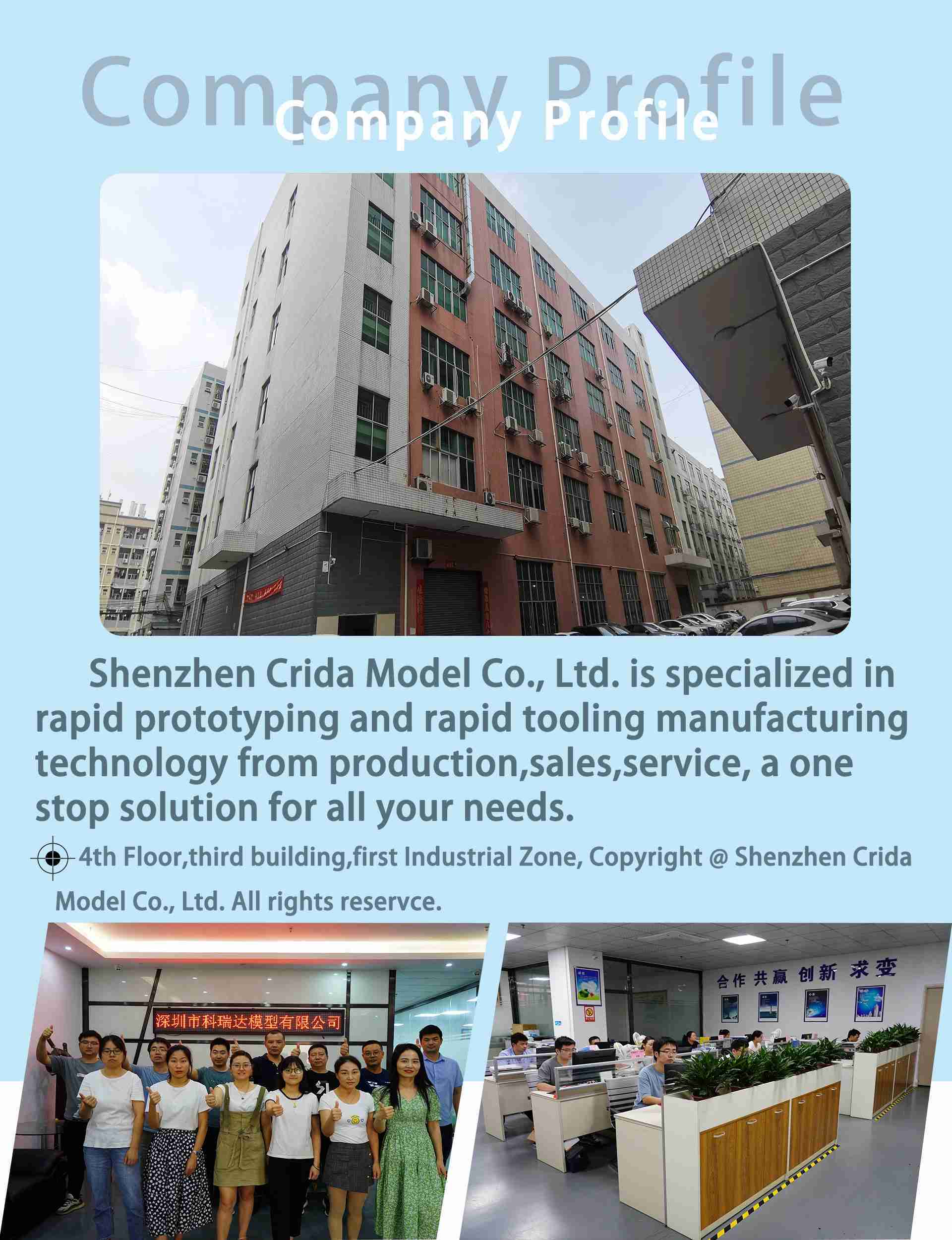

| Company Info. |

| Shenzhen Crida Model Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

OEM ODM Wire Bending Machine Made Stainless Steel Wire Bending Custom Wire Forming

Products Description

Crida delivers comprehensive custom metal fabrication solutions, including precision metal bending, welding, punching, rolling, and sheet metal fabrication tailored to your exact specifications. We specialize in carbon steel, alloy steel, heavy plate steel , and stainless steel fabrication, alongside exotic metal processing (titanium, Inconel, copper alloys). Our end-to-end capabilities encompass custom metal parts manufacturing, welding, metal machining (CNC milling/turning), heat treating, and precision plate cutting/beveling. We further support projects with metal forming, prototyping, shearing, flattening, straightening, and surface finishing (painting/powder coating). From prototypes to high-volume production, Crida combines advanced technology with ISO/AS9100-compliant workflows to craft complex geometries, structural assemblies, and industrial components with ±0.1mm tolerances. Trust us for seamless integration of design, fabrication, and finishing—all under one roof.

Advantages

1. Tolerance ±0.02

2. One-stop solution services

3. Well-experienced in providing production for Custom design and OEM orders.

4. Reliable quality, precision tolerance

5. Several years of experience in producing and processing.

6. Quick sample responses 3-7 days

7. Provides 7*24 hours of after-sales service to provide users with the most satisfactory products.

8. Global delivery service

Technical Parameters

| Product Name | Sheet Metal Fabrication Service |

| Process | sheet metal processing, Bending, Welding |

| Machine | Laser cutting machine, Bending Machine, Welding |

| Materials | Stainless Steel sheet, Galvanized sheet, Aluminum Plate, Cold Plate, Iron plate, Pickling plate |

| Features | Customized Design; Sample Order Accepted Short Delivery time; Competitive Prices Long-time quality Insurance. Professional after-sales services |

| Surface Treatment | Brushing, Polishing, Electrophoresis, Anodizing, Powder Coating, Plating, Silk screen, Laser Engraving |

| Drawing Format | 3D/CAD/DWG//STEP/PDF |

| Color | Customized |

| Minimum Order Quantity | Small Orders Accepted |

| Application | Auto /Moto Parts, Machinery Parts, Lighting Components, Hardware Accessories, Electric Motor Products |

| Packing Details | EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton |

| Quality Control System | Incoming inspection, process inspection, finished product inspection, and delivery inspection |

Technical Support & Services

Crida provides unparalleled technical support for our sheet metal welding parts, backed by a dedicated team of engineers and technicians committed to your operational success. We offer end-to-end assistance—from product selection and customization guidance to expert installation support, operational troubleshooting, and preventive maintenance. For complex challenges, our specialists deliver rapid on-site repair services and technical advice to resolve weld integrity, fitment, or performance issues. We further empower your team with tailored training programs on best practices and timely updates for process optimization. Whether you need design validation, failure analysis, or emergency field service, Crida ensures minimal downtime and maximized part longevity. Contact us 24/7 for solutions engineered to keep your welded assemblies performing at peak efficiency.

Core Support Services

1. Design & Selection: Customization advice + material/process

optimization

2. Installation & Operation: Step-by-step guidance for error-free integration

3. Proactive Maintenance: Scheduled checks + on-site repair protocols

4. Emergency Troubleshooting: Root-cause analysis (porosity, distortion, cracking)

5. Continuous Improvement: Product upgrades + efficiency consultations

6. Knowledge Transfer: Certified training (AWS standards, weld inspection)

FAQ

Stainless Steel (304, 316L for corrosion resistance)

Aluminum (5052, 6061 for lightweighting)

Carbon Steel (A36/1018 for structural strength)

Exotics (Titanium, Copper Alloys)

Material selection is tailored to your functional requirements.

Production Batches: 10–15 days (standard), 7 days (rush)

Expedited options available for urgent projects.

|