| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Prefabricated Steel Structure |

|---|---|

| Brand Name: | TSIN |

| Model Number: | TSIN |

| Certification: | ISO, CE, SGS |

| Place of Origin: | Shandong, China |

| MOQ: | 1000 sqm |

| Price: | USD 40-60 / sqm |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 100,000 sqm / month |

| Delivery Time: | 6 weeks after shop drawing get approval |

| Packaging Details: | Packed on steel pallet with fixture and loaded into 40'HQ/OT |

| Application Fields: | Warehouse, Multi-building, Workshops & plants, Hospital, School, Office, Apartment |

| Drawing Design: | AUTOCAD, SOLIDWORKS, TEKLA |

| Maximum Roof Load (lb./sq.ft):: | 20+lb/sq.ft |

| Raw Steel Material: | Q235B, Q355B, ASTM A36 |

| Frame Type: | Portal Frame |

| Design Parameter: | Wind Load,Snow Load And Earthquake |

| Working Scope: | Design, Fabrication, Installation |

| Life Span: | Around 30~50 Year |

| Surface treatment: | Surface treatment |

| Standard: | GB, ASTM, EN, ISO, AS/ANS |

| Company Info. |

| Qingdao Tsin Steel Structure Construction Technology Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

| Dimension | Length * width * eave height, roof slope |

|---|---|

| Type | Single/double/multi-slope; Single/double/multi-span; Single/double/multi-floor |

| Foundation | Concrete and steel foundation bolts |

| Column and Beam | Hot rolled or welded H steel Q355B, high strength bolts connection, straight or variable cross-section |

| Bracing | X or V type bracing made from angle steel or pipe |

| C/Z Purlin | Q235B C/Z section steel (C160-300 or Z160-300) |

| Roof/Wall Panel | Single colorful corrugated steel sheet or sandwich panel with EPS, rock wool, glass wool, or PU insulation |

| Accessories | Skylight belts, ventilators, down pipes, gutters, doors, windows |

| Surface Treatment | Painting or hot dip galvanized |

| Package | Nude or packed on steel pallet in 40'HQ/OT containers |

We implement rigorous quality control measures throughout the project lifecycle, including:

Qingdao Tsin Steel Structure Construction Technology Co., Ltd. provides integrated solutions for steel structure workshops, warehouses, and multi-storey buildings, including:

Our production capacity reaches 2,500 tons per month across 20,000m² of workshop space (30,000m² total factory area). We operate complete production lines for H steel, C/Z purlins, and various steel sheet and sandwich panels.

Based in Shandong, China since 2025, we serve clients in South America, Africa, Oceania, and other global markets with a team of 5-10 professionals.

Pre-production samples and final inspections before shipment ensure consistent quality standards.

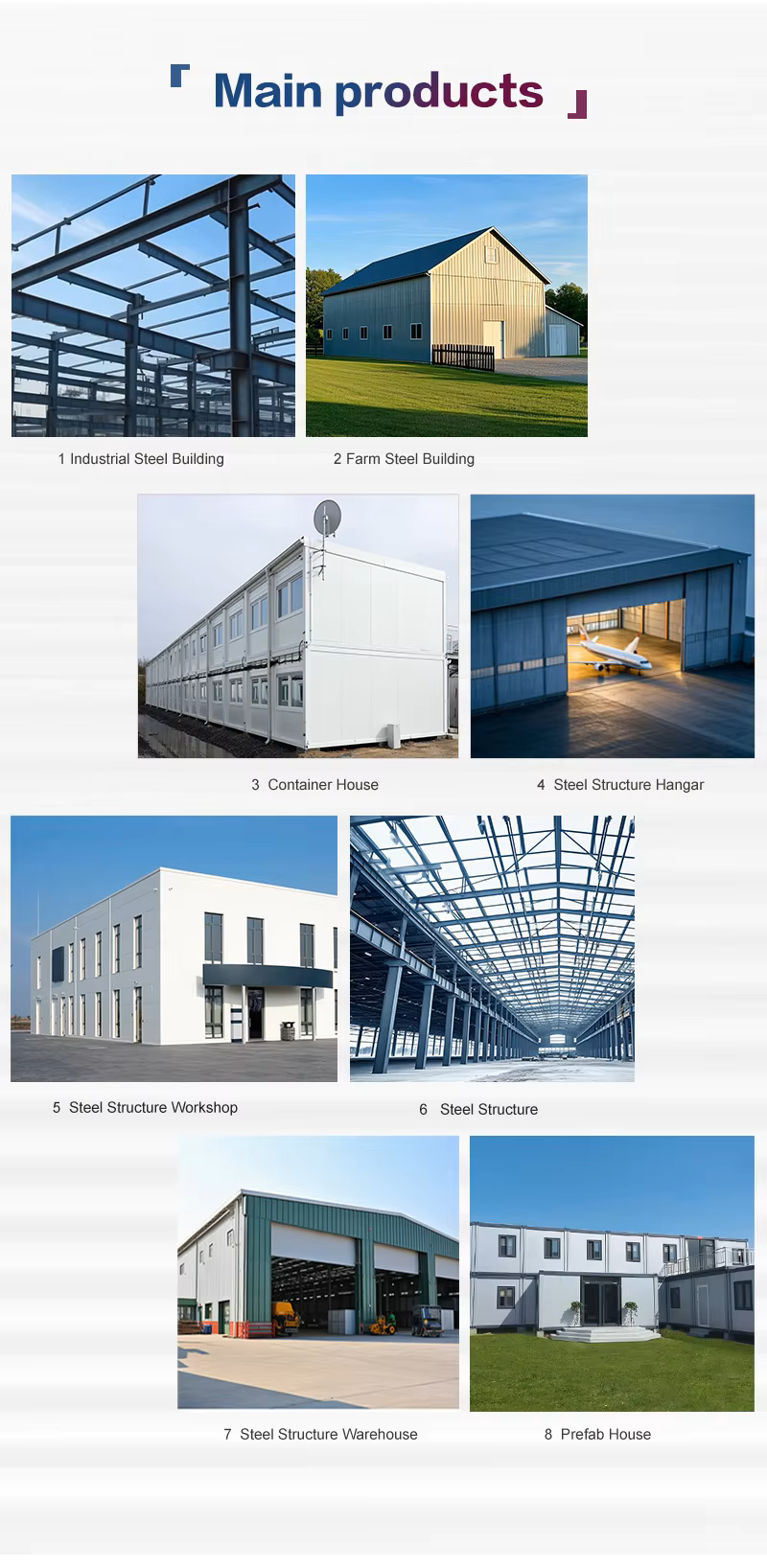

Steel Structure Warehouses, Workshops, Buildings, Poultry Houses, and Prefab Houses.

20+ years experience providing complete steel structure solutions with integrated design, fabrication, and installation services.

We accept FOB, CFR, CIF, EXW delivery terms and T/T, L/C, Cash payments in USD, EUR, AUD, CNY.

|