| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | PVC Waterproof Membrane |

|---|---|

| Brand Name: | HAOBANG |

| Model Number: | 1.5mm PVC waterproof membrane |

| Certification: | ISO |

| Place of Origin: | Shandong,China |

| MOQ: | 1,000 square meters |

| Price: | Price negotiable |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 600000 square meters per year |

| Delivery Time: | 6-7 work days |

| Packaging Details: | Packed in Roll and on Pallet |

| Color: | White |

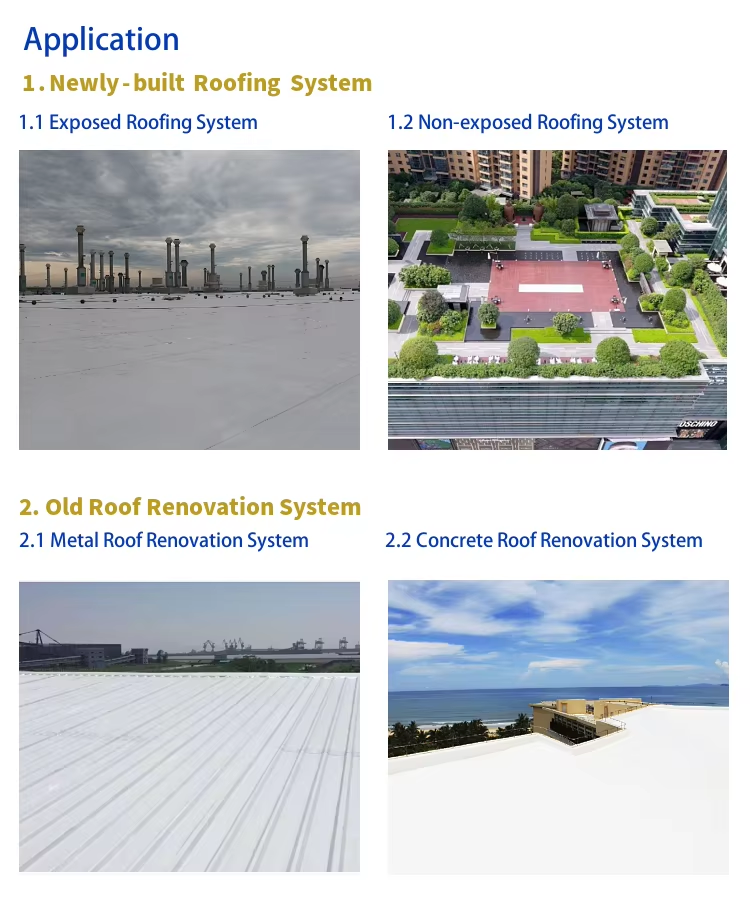

| Application: | Roof |

| Root Penetration Resistance: | No Penetration |

| Low Temperature Performance: | Excellent |

| Warranty: | 1 Year |

| Length: | 10m-20m |

| Tear Strength: | ≥50N |

| Raw Material: | PVC |

| Installation Method: | Hot Air Welding |

| Thickness: | 1.2mm-2.0mm |

| Single Package: | 200X10X10 cm |

| Chemical Resistance: | Excellent |

| Water Impermeability: | No Leakage |

| Elongation At Break: | ≥250% |

| Roll Length: | 25 meters |

| Company Info. |

| Weifang Haobang Waterproof Materials Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

2.0mm PVC Waterproofing for Green Roofs Highly Flexible Membrane

Product Description

| Product Name | 1.5mm PVC Roofing Membrane (Smooth Version) |

| Material | PVC |

| Color | White |

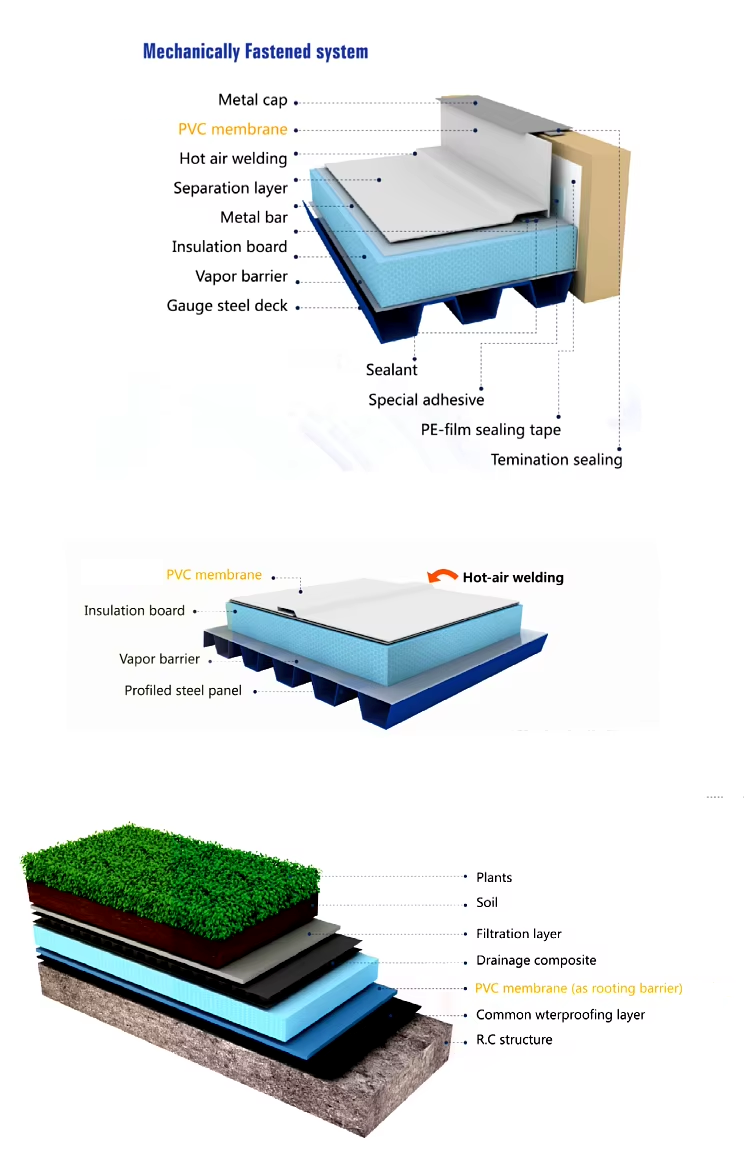

HAOBANG roofing membranes utilize UV-stabilized PVC compounds precision-formulated with optimized ratios of flexibilizers, anti-degradants, thermal stabilizers, mineral reinforcements, and process modifiers. This engineered composite undergoes continuous extrusion-calendering to create homogeneous sheets where inherent thermoplastic properties facilitate seamless thermal fusion installation. The resultant high-performance sheeting delivers exceptional environmental durability with proven resistance to aggressive chemical exposure and industrial atmospheric contaminants.

Specification

| Type | Thickness(mm) | Width(m) | Length(m) | Application |

| PVC-SM | 1.2/1.5/2.0 | 2.0 | 20 | Detail Treatment and Non-e xposed Roofing |

| PVC-FB | 1.2/1.5/2.0 | 2.0 | 20 | Fully Adhering System |

| PVC-FR | 1.2/1.5/2.0 | 2.0 | 20 | Mechanical Fixed System |

Advantages

Exceptional long-term UV radiation tolerance;

Superior thermal fusion integrity;

Enhanced cryogenic flexural performance;

Outstanding dimensional retention stability;

Advanced elongation capacity;

High-impact damage tolerance;

Optimized solar reflectance index;

Energy-conservative sustainable life-cycle profile (100% reclaimable)

Specification

Each production unit is sheath-protected with coextruded PE film, featuring a standardized 2.0m width with custom-cut lengths corresponding to material gauge.

Thickness-Length-Mass Profile:

0.8mm gauge: 30m linear footage

*Nominal mass range: 48-50kg/unit*

1.2mm gauge: 25m linear footage

*Calibrated mass: 62-64kg/unit*

1.5mm gauge: 20m linear footage

*Unit mass: 62-64kg*

1.8mm gauge: 15m linear footage

*Mass parameter: 56-58kg/unit*

2.0mm gauge: 15m linear footage

*Standard unit mass: 62-64kg*

FAQ

Q: Which financial settlement channels are available?

A: We process transactions via wire transfer, documentary credit,

PayPal, and major credit cards. Project-scale procurements qualify

for structured payment solutions including installment financing.

Q: Are material compliance certificates provided?

A: Certified documentation packages (ISO 9001, SGS test reports,

CE/GB standards compliance) accompany all commercial shipments upon

request.

Q: What's the protocol for non-conforming deliveries?

A: Our quality team initiates claim resolution within 24 operational

hours. Verified defects trigger contractual remedies: replacement

shipments or full reimbursement.

|