| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Precision Steel Tube |

|---|---|

| Brand Name: | TORICH |

| Model Number: | SA139 |

| Certification: | ISO9001 ISO 14001 TS16949 |

| Place of Origin: | Zhejiang/China |

| MOQ: | 1Ton |

| Price: | 800-100 USD/Ton |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 60000 Ton/Tons per Year |

| Delivery Time: | 20-30days upon products |

| Packaging Details: | In bundles or in wooden boxes. |

| Application: | Structure Pipe,Hydraulic Pipe,Construction,Fluid Pipe,Oil Pipe |

| Outer diameter(round): | 30 - 426mm, |

| Thickness: | 2 - 50 mm, |

| Standard: | ASTM,DIN,GB,JIS,API |

| Technique: | ERW,Hot Rolled/Cold Drawn |

| Grade: | Grade A B C D E |

| Section shape: | Round,Rectangular |

| Length: | 6M or as requirement,As customer's require |

| Company Info. |

| TORICH INTERNATIONAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

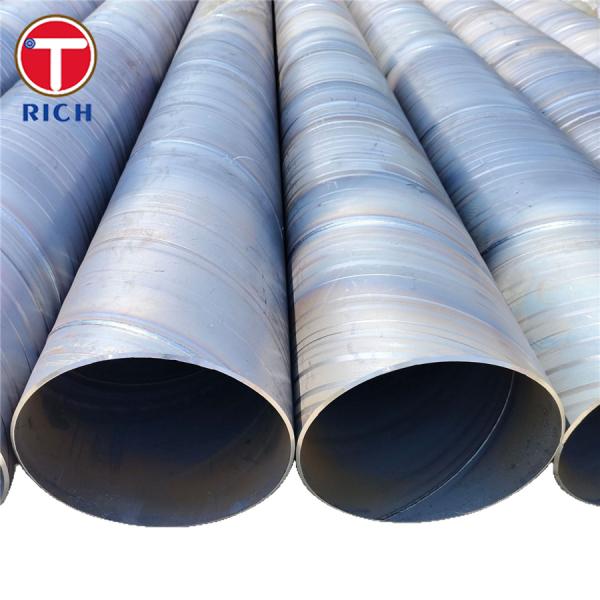

Material

These pipes are manufactured from carbon steel conforming to the

ASME SA139 (ASTM A139) specification for electric-fusion (arc)

welded spiral‑ or straight‑seam pipe. They are designed for

conveying liquids, gases, or steam and are suited to high‑strength

structural and pressure‑resistance requirements (cited per ASTM

A139/A139M).

Specifications

• Nominal Pipe Size (NPS): 4″–92″ (typical automotive use: 4″–36″)

• Wall Thickness: up to 1.0 inch (25.4 mm) typical

• Form: Spiral‑welded (SAW/SSAW) pipe, saw‑cut ends,

plain/beveled/treaded finish

Chemical Composition

| Grade | C (max %) | Mn (max %) | P (max %) | S (max %) |

|---|---|---|---|---|

| A | 0.25 | 1.00 | 0.035 | 0.035 |

| B | 0.26 | 1.00 | 0.035 | 0.035 |

| C | 0.38 | 1.20 | 0.035 | 0.035 |

| D | 0.30 | 1.30 | 0.035 | 0.035 |

| E | 0.30 | 1.40 | 0.035 | 0.035 |

Mechanical Properties

| Grade | Min Yield Strength (psi / MPa) | Min Tensile Strength (psi / MPa) |

|---|---|---|

| A | 30,000 psi (~205 MPa) | 48,000 psi (~330 MPa) |

| B | 35,000 psi (~240 MPa) | 60,000 psi (~415 MPa) |

| C | 40,000 psi (~290 MPa) | 70,000 psi (~485 MPa) |

| D | 42,000 psi (~290 MPa) | 60,000 psi (~415 MPa) |

| E | 52,000 psi (~360 MPa) | 66,000 psi (~455 MPa) |

Major Characteristics

– High strength and toughness for pressure resistance.

– Fabrication flexibility: spiral welding enables large diameter

and long lengths.

– Consistent quality through standardized electric‑fusion weld

process.

– Economical production compared to seamless or LSAW alternatives.

– Suitable for straight or saw‑cut end finishes for custom

assembly.

Applicable Standards

ASTM A139 / ASME SA139 provides grade definitions, chemical and

mechanical requirements, and testing protocols.

Applications in the Automotive Industry

– Structural frames or supports: large‑diameter tubular supports or

lift shafts.

– Fluid transport systems: low‑pressure oil or coolant delivery

under vehicle assembly.

– Hydraulic or pneumatic conduit: robust piping for material

handling or robotics within plants.

– Engineering equipment: machinery and structural piping in

automotive manufacturing facilities.

A: manufacturer,also can do trading.

A: Generally speaking,it is 10-15 days if the goods are in stock,or it is 30-40 days if the goods are not in stock,

it is according to quantity.

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

A: Payment<=2000USD, 100% in advance. Payment>=2000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact with me.

|