| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Customized Carbide Tool |

|---|---|

| Brand Name: | AMG |

| Model Number: | Standard/Customized |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 3 |

| Price: | Request Quote |

| Delivery Time: | 3-7 days for standard products/7-10 days for non-standard products |

| Material: | Carbide |

| Coating: | TiAlN/AlTiN/TiCN /customized |

| Diameter: | 6mm |

| Product name: | Heat Resistant Carbide End Mill |

| Suitable for: | Alloy Steel,Stainless Steel,Titanium Alloy |

| Express: | Air,TNT,DHL,EMS,Express |

| Company Info. |

| Changzhou AMG Precision Tool Manufacturing CO., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

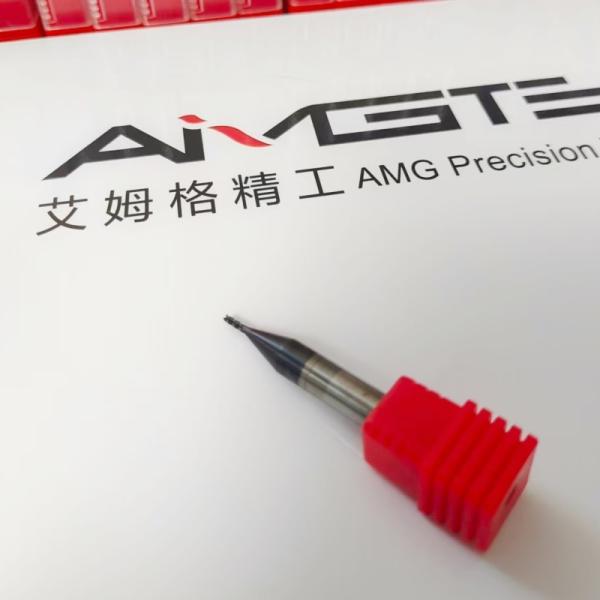

The D1.3×4×SD6×50-4F external cooling end mill from AMG is specifically designed for high-precision milling of stainless steel and other hard -to-machine materials. Featuring a right-hand cut and right-hand helix with a four-flute design, this micro-diameter solid carbide tool delivers excellent surface finish, dimensional accuracy, and cutting stability. It is ideal for customers seeking precision machining solutions in sectors such as medical devices, precision molds, aerospace, and electronics.

Parameter | Value |

Cutting Diameter | 1.3 mm |

Flute Length | 4 mm |

Shank Diameter | 6 mm |

Overall Length | 50 mm |

Number of Flutes | 4 |

Helix Direction | Right-hand |

Cutting Direction | Right-hand |

Cooling Type | External |

Material | Ultra-fine grain solid carbide |

The tool rotates clockwise, performing right-hand cutting with four flutes for stable chip removal. External coolant is directed precisely to the cutting edge to dissipate heat and reduce friction, preventing material work-hardening and minimizing tool wear. This ensures optimal performance in continuous or semi-continuous machining tasks requiring high surface.

Perfect for contour milling: Micro-diameter and short flute length provide superior control in delicate profile cutting.

High wear resistance: Premium ultra-fine grain carbide offers excellent durability and thermal stability.

Excellent surface finish: Four-flute configuration ensures finer cutting passes and smoother surfaces.

Efficient cooling: External cooling design enhances heat control during stainless steel processing.

Versatile compatibility: Standard 6mm shank fits a wide range of clamping systems.

When selecting a tool for precision contour milling, key factors include flute count, cutting diameter, flute length, and cooling strategy. The D1.3×4×SD6×50-4F is optimized for micro-scale operations and tight-tolerance applications. It is recommended to use this end mill with high-speed spindles and high-pressure coolant delivery for best results. AMG also offers customized solutions to meet specific machining requirements.

Q: What materials can this tool process?

A: Ideal for stainless steel, alloy steel, and cobalt-chromium

alloys.

Q: Are special machining parameters required for contour milling?

A: Yes, lower feed rates and moderate spindle speeds are

recommended to ensure surface integrity and cutting stability.

Q: How long does the tool last?

A: Tool life depends on material, feed rate, and cooling

efficiency. With proper usage, multiple reuses are possible.

|