| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Pre-Insulated Pipe Production Line |

|---|---|

| Brand Name: | HUASHIDA |

| Model Number: | 110-2200mm |

| Certification: | CE, ISO9001:2008 |

| Place of Origin: | QINGDAO,CHINA |

| MOQ: | 1 |

| Price: | US$200,000.00 - 1,000,000.00 |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram |

| Supply Ability: | 100 Unit/Year |

| Delivery Time: | 60DAYS |

| Packaging Details: | Standard Package |

| Raw Material: | HDPE |

| Product Type: | Plastic Pipe |

| Cutting Method: | Chipless Cutting |

| Application: | for Producing Pre-Insulated Pipe Jacket |

| Pipe Diameter: | 110-2200mm or Customized |

| Company Info. |

| Qingdao Huashida Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

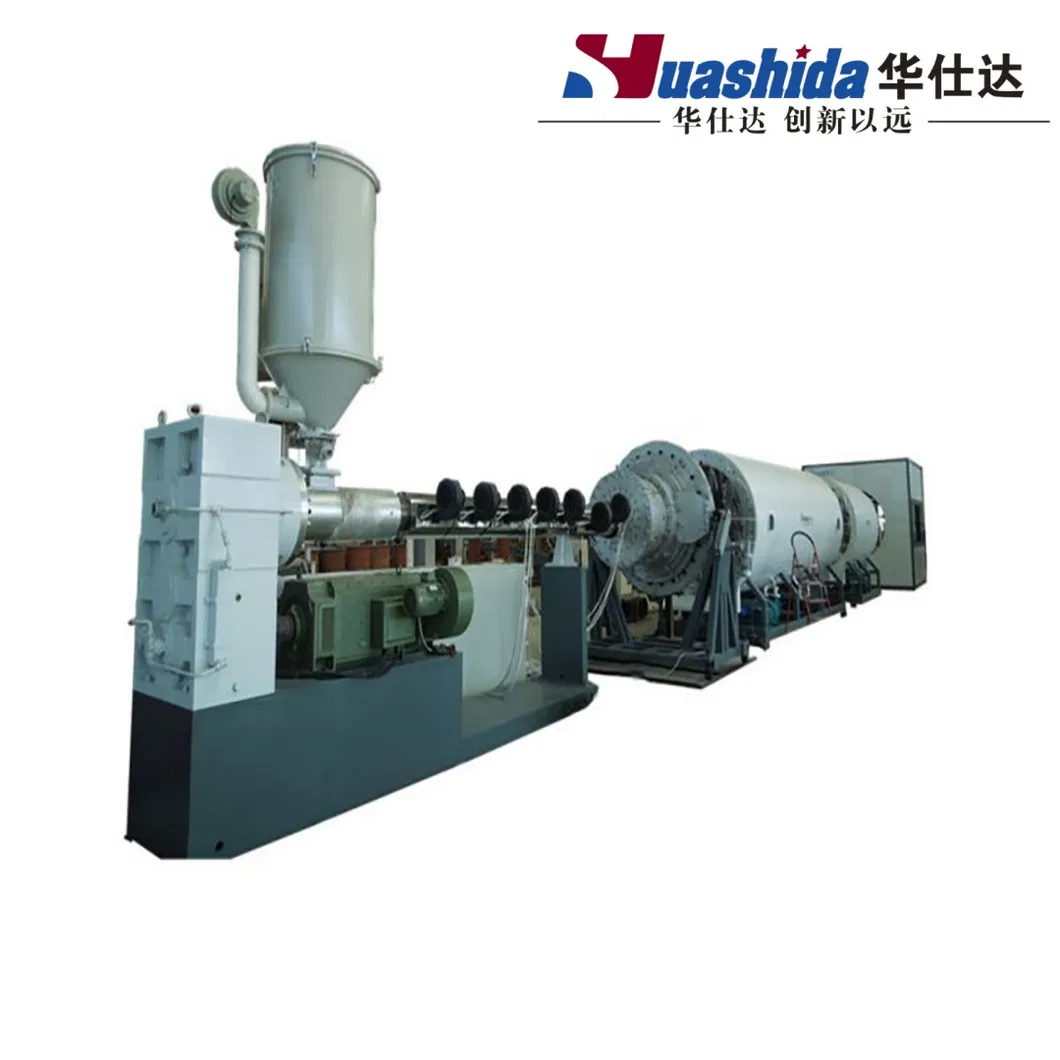

Pipe diameter range: 110-2200mm

The vacuum-calibrated polyurethane-insulated pipe is a

high-performance pre-insulated piping system. It primarily consists

of a core steel pipe, a polyurethane (PU) foam insulation layer,

and a protective plastic outer casing, among other components.

Key Features:

Production Method: Utilizes a vacuum calibrating technique.

Quality: Ensures smooth internal and external walls.

Durability: Offers a long service life with excellent

anti-corrosion properties.

Performance: Delivers outstanding mechanical characteristics.

It is suitable for a wide range of thermal and cryogenic insulation

applications, including hot/cold water supply, petroleum pipelines,

and high/low-temperature pipeline systems.

| Style | PE-110/500 | PE-655/1380 | PE-960/1860 | PE-1155/2200 |

| Main Extruder | SJ-75/33 | SJ-120/33 | SJ-150/33 | SJ-150/33 |

| Pipe diameter | Φ110-600mm | Φ655-1380mm | Φ960-1860mm | Φ1155-2200mm |

| Capacity | 250-350kg/h | 700-900kg/h | 1000-1200kg/h | 1350kg/h |

| Installed power | 160kw | 480kw | 580kw | 650kw |

| Length | 26m | 36m | 45m | 45m |

High-efficiency single screw extruder

---Single screw is with barrier & mixing head; new model barrel

with slotting (channel), Both make the security of good

jellification, large output and stable performance.

Die-Head

Die-head is mainly composed of mandril, neck mold, spiral body,

cover, die-head body, bolts, and heating rings.

The inside surface touching with plastic materials is polished and

chrome plated to ensure plastic materials flow smoothly and to

ensure no rusting. The uniformity of pipe wall thickness can be

adjusted by bolts. The copper calibrating sleeve fixed in the

die-head is mainly used to cool down the fresh pipe and to

calibrate the pipe outer diame

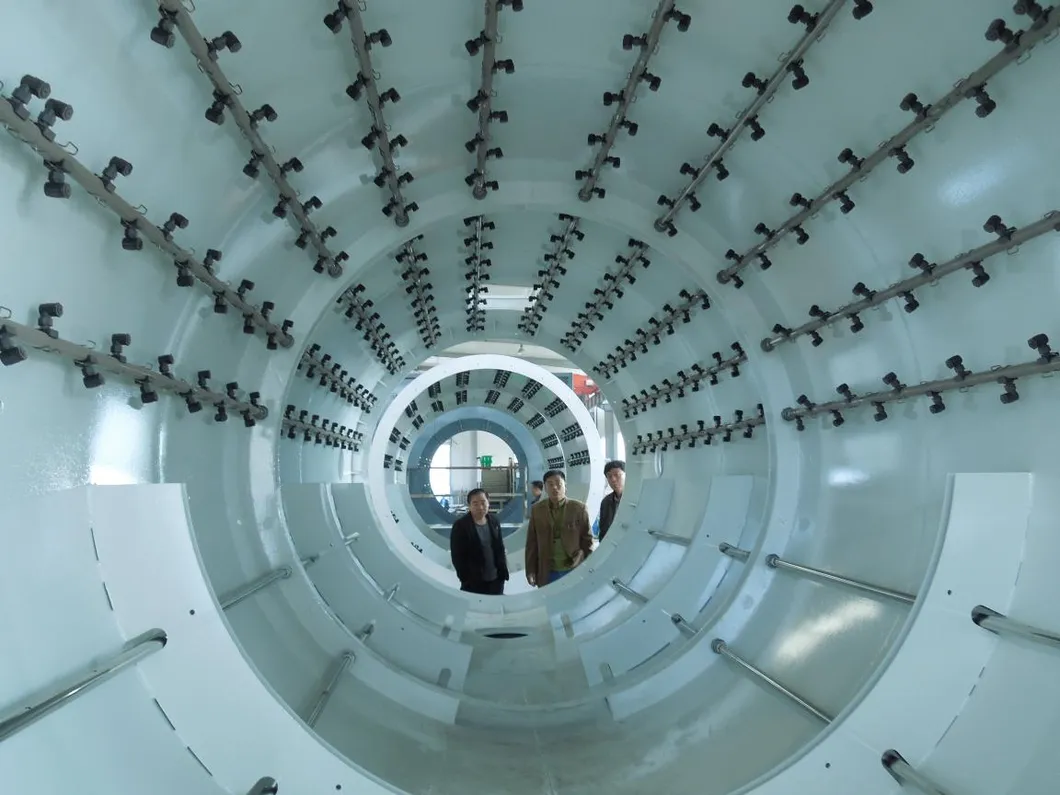

Vacuum Calibration Tank

The vacuum calibration tank is mainly composed of a frame,

stainless steel tank, vacuum system, spray cooling system, position

adjustment device. The vacuum pump exhausts the air from the sealed

tank to pressurize the fresh pipe cling to calibrate the copper

sleeve and to calibrate the outer diameter. Spray nozzles spray

cooling water from all directions on pipe surface to cool down the

pipe promptly.

Haul-off Machine

The haul-off machine is mainly composed of a driving device, track,

clamping structure, adjusting system, side plate and foundation

bed. Haul-off caterpillars are driven by AC motor with frequency

conversion control to adapt to different extrusion speeds.

An automatic length measuring device realizes cutting at a set

length.

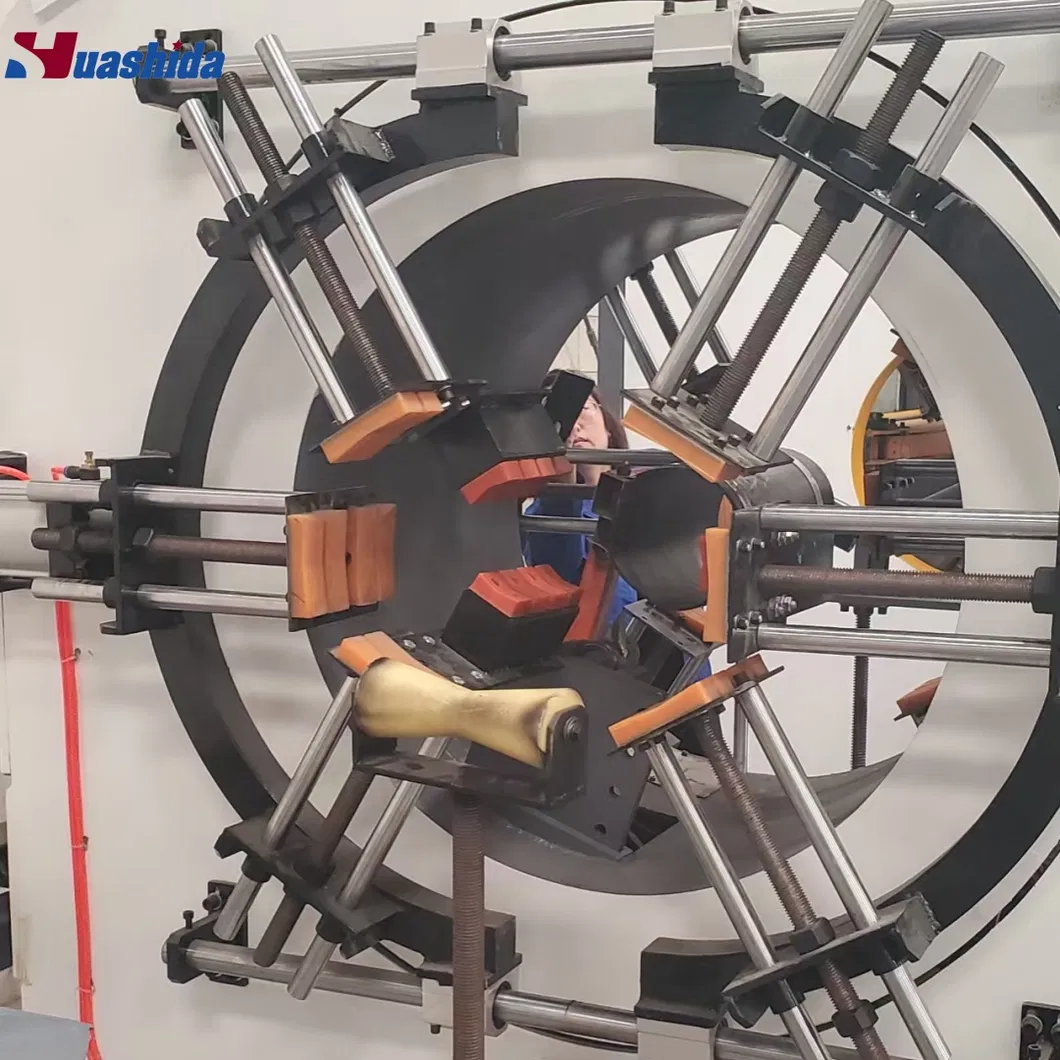

Chipless cutting

It adopts the blade punching principle to realize no-dust cutting.

It is mainly composed of a cutting device, clamping device,

structure synchronous movement device and frame.

Control system

ABB frequency converter or EUROTHERM speed controller

Japan RKC temperature controller

SIEMENS AC contactors

A controlling system can be designed according to customers'

requirements.

|