| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Composite Geogrid |

|---|---|

| Brand Name: | SZ |

| Model Number: | EGA |

| Certification: | ISO,CE |

| Place of Origin: | CHINA |

| MOQ: | 30000 square meter |

| Price: | $0.3-$2.0/SQM |

| Payment Terms: | ,L/C,T/T |

| Supply Ability: | Normaly 30000 square meter per day. Exacltly capacity will subject to specification. |

| Delivery Time: | 5-8 working days |

| Packaging Details: | Palletized packing |

| Product Name: | Composite Geogrid |

| Function: | Filtration And Anti Cracking Reinforcement |

| Usage: | City Greening |

| Process: | By Glue or Stitch |

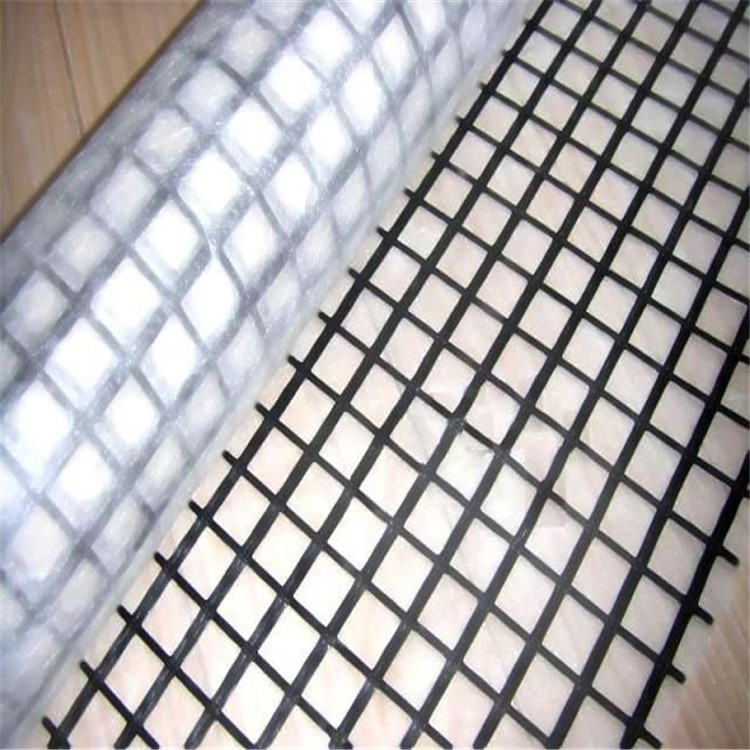

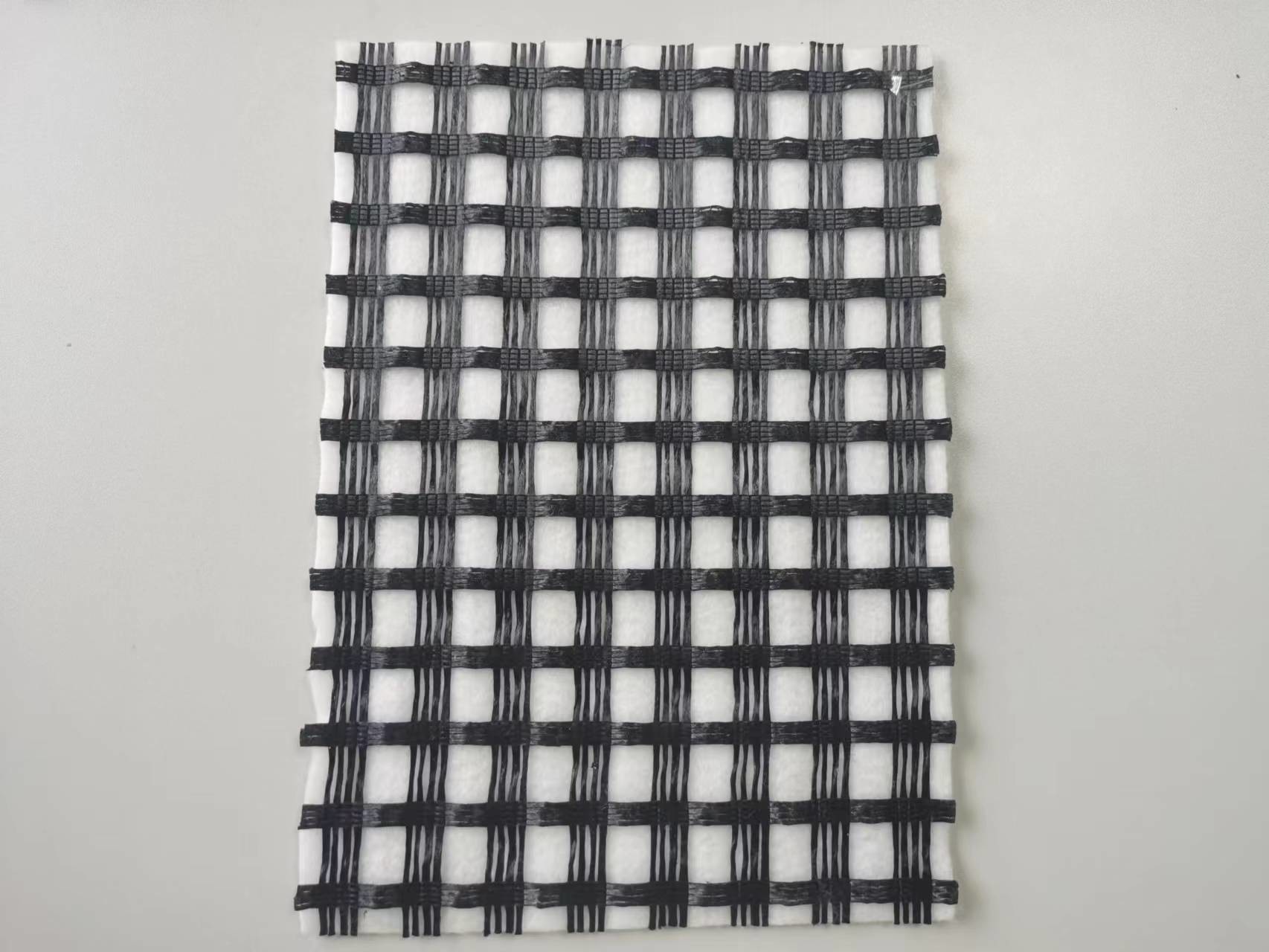

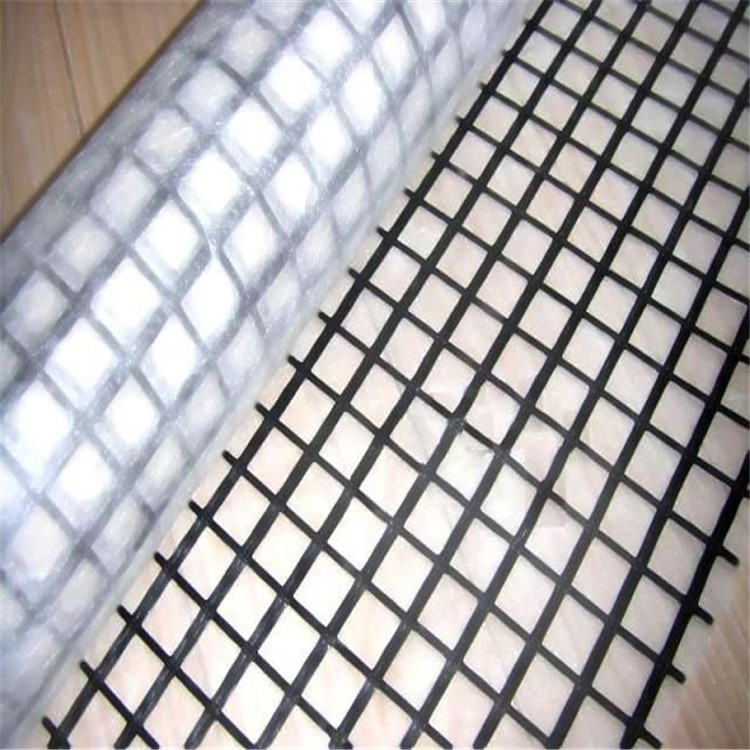

| Material: | Geogrid composite with Geotextile |

| After-sale Service: | Online technical support |

| Roll width: | 1-6m |

| Tensile strength: | 30-300kn |

| Company Info. |

| Shenzhou Earth Working Material Co. Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Composite Geogrid is a high-performance geosynthetics composed of a variety of materials, mainly used for foundation reinforcement, soil stabilization and structural enhancement in civil engineering.

Definition and Types

Material composition

Geogrids are usually made of a polymer matrix (such as polypropylene, polyester) combined with reinforcing materials (glass fiber, steel, etc.). Common types include:

Glass fiber composite grid: With glass fiber as reinforcement, it has the characteristics of high tensile strength and acid and alkali resistance, and is often used in pavement engineering.

Polyester/polypropylene composite grid: A mesh structure is formed by weaving or welding process, which is used for reinforced retaining walls or slope protection.

Structural design

It is divided into two-dimensional plane grid or three-dimensional structure, and the mechanical properties are optimized through the synergy of materials.

Fiberglass Geogrid | EGA 30-30 | EGA 50-50 | EGA 80-80 | EGA 100-100 | EGA 120-120 | EGA 150-150 | EGA 200-200 | EGA 300-300 | |

Mesh size (mm) | 25.4x25.4 or 12.5x12.5 or 50.8x50.8 | ||||||||

Breaking strength ≥(kN/m) | MD | 30 | 50 | 80 | 100 | 120 | 150 | 200 | 300 |

CMD | 30 | 50 | 80 | 100 | 120 | 150 | 200 | 300 | |

MD/CMD | 4/4 | ||||||||

Thernal tolerance(℃) | -100~280 | ||||||||

Width≤(m) | 6 | ||||||||

Nonwoven Geotextile | |

Material | PP or PET |

Mass per unit area | 20g---100g/㎡ |

Roll Width | 3.95 /5.95 m |

Roll Length | 50/100 m |

Manufacturing process and performance characteristics

Production process

Thermoplastic molding: forming a grid structure through high-temperature molding or ultrasonic welding, such as the rib welding process of steel-plastic grid.

Woven composite: weaving fiber materials (such as glass fiber) with polymer substrates and coating them with resin to enhance durability.

Key performance

High strength: tensile strength can reach 30-200 kN/m, which is better than single material grid.

Corrosion resistance: suitable for engineering scenarios in acidic and alkaline environments or long-term exposure.

Water permeability and reinforcement: allowing water to pass through while enhancing soil stability and preventing landslides.

High tensile strength, anti-tearing and high bursting strength.

Function of isolation, drainage, reinforcement, protection,

anti-seepage and etc .

|