| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Rubber Duckbill Check Valve |

|---|---|

| Brand Name: | Liang He |

| Model Number: | XH-41 |

| Certification: | ISO 9001 |

| Place of Origin: | Henan,China |

| MOQ: | 1 piece |

| Price: | $14.3-18.6 per set |

| Payment Terms: | T/T,D/A,D/P,Western Union,MoneyGram,L/C |

| Supply Ability: | 8000 piece per month |

| Delivery Time: | 3-7 day |

| Packaging Details: | cartons,wooden cases |

| Warranty: | 1 year |

| material of body: | NR, EPDM, NBR |

| Working site: | Coast, beach, dock, reservoir, municipal flood discharge, sewage |

| OEM: | Support |

| Product drawing: | offer |

| Stock: | a large of stock |

| Flange Standard: | EN,DIN,ANSI,JIS,GOST |

| Company Info. |

| Henan Lianghe Pipeline Equipment Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

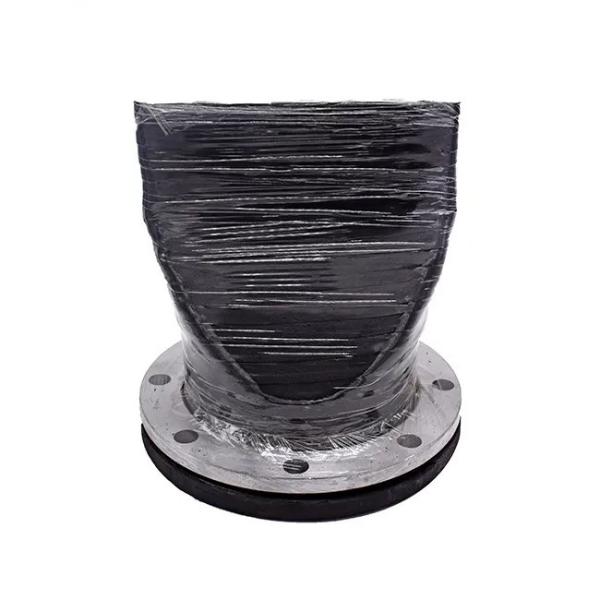

EPDM flange type DN100 duckbill rubber check valve for sewage discharge corrosion abrasion weather resistance

Installation method

1. Prepare for installation: Ensure that the installation environment meets the requirements, including checking the caliber of the flange, pressure level, material and the material of the rubber body of the duckbill valve to ensure that they are suitable for the installation environment. At the same time, consider factors such as temperature, humidity and medium of the installation environment.

2. Check the pipe end face: Use tools and methods to check the pipe end face to ensure that the inclination deviation of the cut end face does not exceed 1% of the outer diameter of the pipe and does not exceed 3mm. This is to ensure the tightness and safety of the flange connection.

3. Flange connection: Use the flange angle ruler to check the verticality of the flange to ensure that the flange and the pipe are connected concentrically, and the bolts can be freely penetrated. The flanges should be parallel, and the deviation should not be greater than 1.5/1000 of the outer diameter of the flange, and should not exceed 2mm. Use bolts of the same specification for connection, each bolt should not be installed with more than one washer, and the bolt should be flush with the nut when fastening to ensure that the connection is tight and seamless.

4. Increase gasket: Add gasket when connecting the flanged duckbill valve to ensure that the gasket size is consistent with the flange sealing surface, and the surrounding size is neat. The flange shall not be buried in the ground, and the flange of the buried pipeline or the pipeline that does not pass through the ditch shall be provided with inspection wells.

5. Precautions: Attention should be paid to avoid the phenomenon of pressure deviation during installation, so as to prevent the medium from leaking out of the pressure deviation and affecting the safety of the pipeline. At the same time, flange connections should avoid installation in floors, walls and casings.

Functions

1. Automatically open and close according to the water pressure

difference, safe and reliable.

2. The positive opening has low water resistance, low starting

pressure, and the flow rate is automatically adjusted according to

the water pressure.

3. The reverse check has good sealing performance, no leakage, and

prevents backflow. The greater the back pressure, the better the

effect.

4. Anti corrosion, anti-aging, strong adaptability, and long

service life.

Main connection size

| Model | Pipe Nominal Diameter | Length(mm) | High(mm) | Flange outside diameter(mm) |

| XH4150-150-F | 50 | 150 | 100 | 150 |

| XH4180-220-F | 80 | 220 | 140 | 200 |

| XH41100-250-F | 100 | 250 | 200 | 225 |

| XH41150-340-F | 150 | 340 | 265 | 275 |

| XH41200-420-F | 200 | 420 | 325 | 338 |

| XH41250-520-F | 250 | 520 | 425 | 400 |

| XH41300-620-F | 300 | 620 | 525 | 485 |

| XH41350-700-F | 350 | 700 | 625 | 525 |

| XH41400-800-F | 400 | 800 | 725 | 588 |

| XH41450-900-F | 450 | 900 | 825 | 625 |

| XH41500-980-F | 500 | 980 | 925 | 688 |

| XH41600-1120-F | 600 | 1120 | 1025 | 800 |

| XH41700-1180-F | 700 | 1180 | 1125 | 969 |

| XH41800-1350-F | 800 | 1350 | 1400 | 1080 |

| XH41900-1500-F | 900 | 1500 | 1525 | 1150 |

| XH411000-1600-F | 1000 | 1600 | 1725 | 1350 |

| XH411200-1840-F | 1200 | 1840 | 1950 | 1485 |

FAQ

Q: What is rubber material?

A: EPDM, CR, NBR, etc. This depends on the work environment and media.

Q: Is the flange galvanized?

A: Yes, we have electronic galvanized and hot-dip galvanized flanges. We also have painted flanges.

Q: Can I customize the logo?

A: Yes, we can provide OEM and ODM services for you.

Q: Can you provide drawings?

A: Yes, we can provide you with the drawings of the duckbill check valve. Please contact us to obtain the drawings of the duckbill check valve.

Q: What is the pressure of work?

A: 1.0-2.5Mpa.

|