| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Spherical Cast Tungsten Carbide |

|---|---|

| Brand Name: | BODA |

| Model Number: | Spherical Cast Tungsten Carbide BD20401 |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | $58-62/Kgs |

| Payment Terms: | Negotiable |

| Supply Ability: | 10 tons/month |

| Delivery Time: | Negotiable |

| Packaging Details: | 50kg/Steel drum,25kg/Steel drum |

| Hardness: | 2700HV0.1 Minimum |

| Charater: | Higher hardness and high wear resistance |

| Process: | Laser Cladding,Arc Welding,PTA, |

| Applications: | PDC bit, oil drill pipe, TC bearing etc |

| Classification: | Carbide, tungsten-based (CTC-Spherical) |

| Manufacture: | Manufacture Fused, crushed and plasma densified |

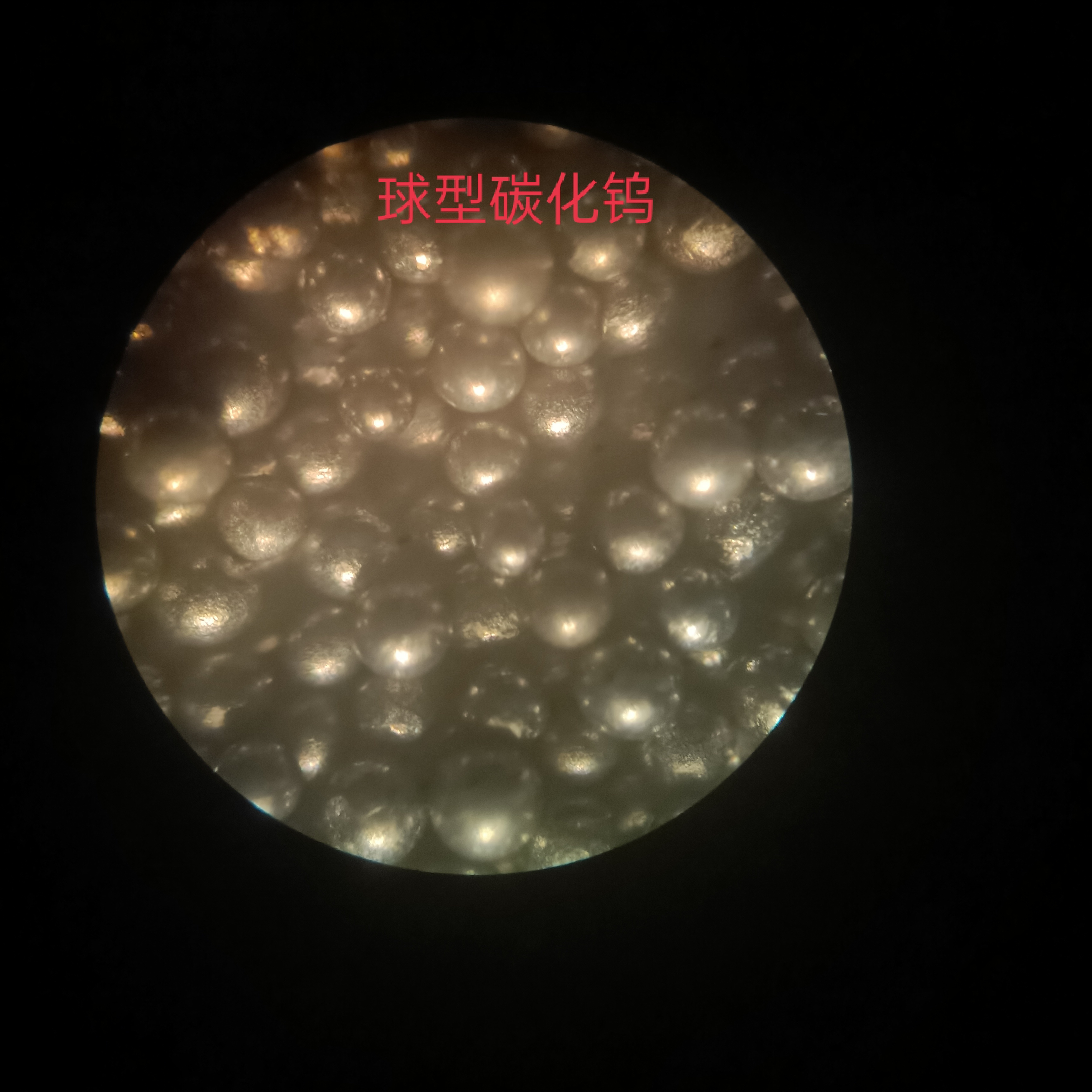

| morphology: | Spherical or nearly spherical |

| Chemical: | WC-W2C |

| PSD: | 100-270Mesh,140-325Mesh |

| Company Info. |

| Zhuzhou Jiangwu Boda Hard-Facing Materials Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Spherical Cast WC, Two-Phase Tungsten Carbide Blend Materials For Hard Face Applications(CTC-S)

Chemicals compositons:

| Grade | W | T.C | F.C | Fe | Ti | MO+CO+Ni | Cr | Vi | SI | |

| BD20401 | Balance | 3.8-4.2 | ≤0.08 | ≤0.5 | <0.1 | <0.2 | <0.1 | <0.05 | <0.02 | |

| Micro-hardness HV 0.1 | Apparent Density g/cm3 | Melting Point ℃ |

| >2500 | >9.0 | 2525 |

Product Introduction:

Spherical Fused Tungsten Carbides (CTC-S) are spheroidally shaped,

two-phase tungsten carbide powders produced by a special melting process.

This makes them the most wear resistant fused tungsten carbide products available on the market.

CTC-S materials are designed to be the hard phase constituent of a wear-resistant surface.

Depending on the surfacing process, they can be blended with self-fluxing alloys or used a filler material for rods, wires, electrodes or infiltration applications.

Overlays containing these materials offer excellent abrasive wear resistance in harsh environments, combined with good impact resistance.

CTC-S offers the best compromise of excellent hardness versus good ductility.

There is a very broad portfolio of applications for these products with different wear conditions.

| Harding facing materials(Tungsten Carbide Series) | |||||

| Product | Boda Code | Regular Particle Size | Main Performance | Spray Process | Applicaitons |

| Cast Tungsten Carbide | CTC/Cast WC | 60-80Mesh | high hardness high wear resistance. | Laser cladding, Arc Welding, PTA, Spray and fuse powder welding | PDC bit, oil drill pipe, TC bearing, etc |

| 80-100mesh | Tool surface reinforcement | ||||

| 100-140mesh | It is especially suitable for surfacing of petroleum and natural gas geological tools | ||||

| 10-2700mesh | Metallurgy, construction, grain and oil processing, mining machinery and other industries | ||||

| 200-400mesh | |||||

| Spherical Cast Tungsten Carbide | SCWC/CTC-S | 100-200mesh | high hardness and high wear resistance. | Laser cladding, Arc Welding, PTA, Spray and fuse powder welding | PDC bit, oil drill pipe, TC bearing, etc |

| 100-270 | Tool surface reinforcement | ||||

| 60-140mesh | It is especially suitable for surfacing of petroleum and natural gas geological tools | ||||

| 100-270mesh | Metallurgy, construction, grain and oil processing, mining machinery and other industries | ||||

| Macro Tungsten Carbide | Macro WC,MWC | 60-80mesh | Hard phase blend component for wear resistance | Laser cladding, Arc Welding, PTA, Spray and fuse powder welding | used as the materials of petroleum |

| 80-200mesh | geological drilling tire body | ||||

| 2000-400mesh | a new type of cemented carbide material. | ||||

| -325mesh | Mining equipment crushers and milling machinery,Heavy equipment mixer blades,decanters or extruder screws. | ||||

| Crystalline Tunsten Carbide | CTP | 60-325Mesh | strength and wear resistance | Vibration and liquid Metal Infitration | petroleum drilling diamond bits |

| 100-200mesh | as the raw materials of oil perforation pills,high temperature combustion chamber spraying coating | ||||

| 140-325mesh | wear resistance and high temperature resistance parts coating for slot or warehouse crashing parts,foklift buckets,crane hopper,screw feeder,ingot tongs and grind device components. | ||||

| Chromium Carbide | Cr3C2 | 140-325mesh | High temperature wear,oxidation and corrosion resistance | Atmospheric plasma spray/combustion powder thermospray | Piston rings,high friction coatings,hot forming dies,machine parts,hydraulic valves,wear protection on aluminum parts |

| 325-5um | For long-term protection of steel structure, first choice for all kinds of anti-corrosion engineering coating materials . | ||||

Related Products:

| Product | Regular Particle Size | Main Performance | Spray Process | Applicaitons |

| CTC+NiCrBSi | 150-53um | High hardness translates to excellent abrasion wear with impact resistant | PTA | Oil exploration equipment and down hole drilling tools |

| CTC+NiBSi | 150-53um | High hardness translates to excellent abrasion wear with impact resistant | PTA | Mild steel,stainless steel,Nickel alloys,Heat-treatable steels when preheated to 300℃ to avoid extensive cracking in the overlay |

| SCWC+NiCrBSi | 150-53um | High hardness translates to excellent abrasion wear with impact resistant | PTA,Laser cladding,pray and fuse,spray-fuse | Drill collars and tool joints used on oil exploration equipment. |

| SCWC+NiBSi | 150-53um | High hardness translates to excellent abrasion wear with impact resistant | PTA,Laser cladding,pray and fuse,spray-fuse | Ceramic conveyor screws,Agricultural shearing blades,Drill collars and tool joints used on oil exploration equipment.Heat-treatable steels when preheated to 300℃ to avoid extensive cracking in the overlay. |

| Macro WC+NiCrBSi | 150-53um/100-270mesh | Wear resistance | Oxy-acetylene welding, arc welding, PTA, laser cladding | Mining equipment,Earth moving equipment,Food and chemical processing decanter screws |

| tubular welding rods | #2 Dia7*400mm 20-30mesh | Excellent wear resistance and impact resistance | Welding | Surfacing of workpiece surface in metallurgy, construction, grain and oil processing, mining machinery and other industries. |

| #3 Dia6*400mm 30-40mesh | ||||

| #4 Dia 5*400mm 40-60mesh | ||||

| #5 Dia4*400mm 60-80mesh | ||||

| Flexible welding rope | Dia4mm: F:0.2-0.4mm M:0.4-0.7mm C:0.7-1.2mm | Wear resistance,Anti-Corrosion | Oxy-acetylene Welding | Oil bit, stabilizer , geological bit, feed screw etc. |

| Dia6mm: F:0.2-0.4mm M:0.4-0.7mm C:0.7-1.2mm | ||||

| Dia8mm: F:0.2-0.4mm M:0.4-0.7mm C:0.7-1.2mm |

About Boda:

Q1: Are you a manufacturer?

Answer: Yes, we are factory founded on 2007.

Q2:Can you give me a discount price?

Answer:Sure,It‘s depends on order quantity.

Q3:How can I get a sample?

Answer:free samples is available,but freight charges will be at your

account and the charges will be return to you or deduct from your

order in the future.

Q4: How to confirm the Product Quality before placing orders?

Answer:You can get free samples for some products,you only need to pay

the shipping cost or arrange a courier to us and take the samples.

You can send us your product specifications and requests,we will

manufacture the products accordingly.

Q5: :How do you treat quality complaint?

Answer:First of all, our quality control team will reduce the quality

problem to near zero.

In case of there is a real quality problem caused by us, we will send you free goods for replacement or refund your loss.

|