| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

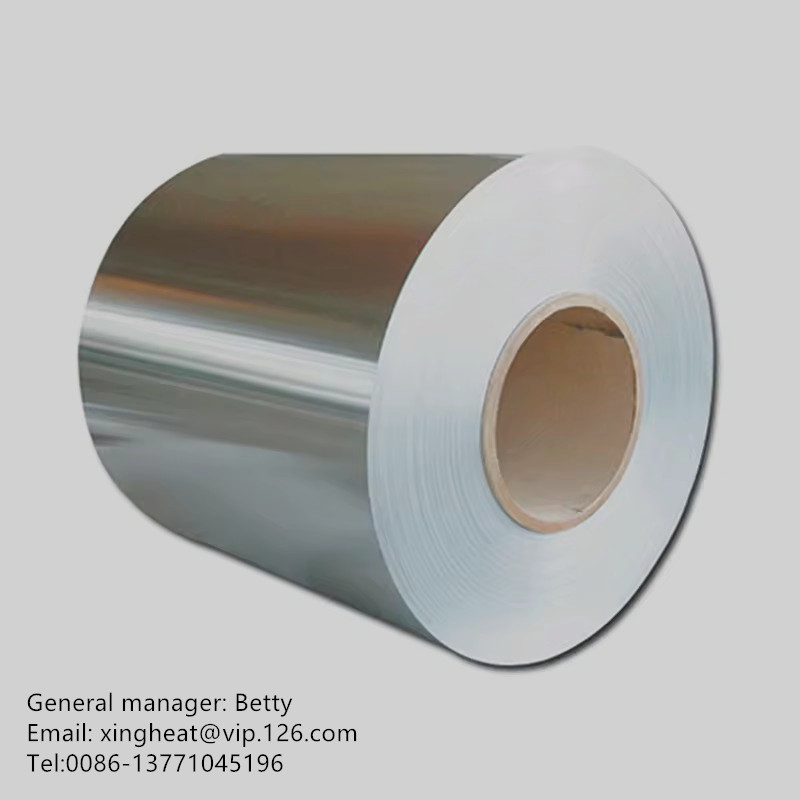

| Categories | Tinplate Coil |

|---|---|

| Brand Name: | HQS |

| Model Number: | 0.15-0.49mm |

| Certification: | reach rohs |

| Place of Origin: | Taizhou,China |

| MOQ: | 25MT/YEAR |

| Price: | USD800-1100/MT |

| Payment Terms: | D/P, L/C, T/T |

| Supply Ability: | 120000MT/YEAR |

| Delivery Time: | 40-70 days |

| Packaging Details: | one container around 25MT |

| Coil Id: | 420mm/508mm |

| Coil Outer Diameter: | Max 2000mm |

| Color: | tin coated |

| Hardenss: | T2,T3,T4,T5,DR7,DR8,DR9,DR10 |

| Length: | coils |

| Package: | standard export package |

| Packing: | Standard Export Packing |

| Sevice: | OEM and ODM |

| Shape: | coils |

| Steel Grade: | MR prime |

| Temper: | T-2,T2.5 T-3, T-4, T-5, DR-7,DR8, DR9, |

| Tolerance: | ±1% |

| Type: | tinplate in coil or sheet |

| Width: | 512-986mm |

| Yield Strength: | 260-580MPa |

| Company Info. |

| MARK METAL(TAIZHOU)CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

tinplate coil T5 tinplate coils Electrolytic tinplate in coil stone sheet food cans tinplate mill factory manufactuer

| Product: | Tinplate sheet, |

| Material: | MR, SPCC |

| Thickness | 0.15-0.49mm |

| Width | 600mm-986mm |

| COIL | 4MT to 8MT per coil |

| Temper: | T2,T2.5 T3 T4 T5; DR8 DR7.5 DR9 |

| Annealing: | BA |

| Tin coating: | 1.1/1.1; 2.2/2.2; 2.8/2.8; 5.6/5.6;2.0/2.0; 2.8/5.6 |

| Surface finish: | Bright, Stone, Silver, Matt |

| Weight per package | 4-8MT |

| standard | JIS G3303; EN10202 ASTM624 |

| Price: | EXW;FOB,CFR,CIF |

| Payment terms: | L/C;T/T;DP; |

| MOQ: | 25 Metric tons |

| Packing: | Seaworthy packing |

| Delivery: | 50 days after advanced deposit or L/C. |

| Appliations: | Food cans, beverage cans, aerosol cans, cosmetics, paint cans, chemicals cans, storage cans, battery,stationery, etc |

| package | SUITABLE FOR EXPORT |

The steel used in tinplate production is typically low-carbon steel, which is chosen for its excellent form-ability and strength. The tin coating is applied to the steel sheet through a process called electrolytic tinning. In this process, the steel sheet is passed through an electrolyte bath, and an electric current is applied to deposit a layer of tin onto the surface of the steel.

products.

|