| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Nickel Welding Wire |

|---|---|

| Brand Name: | Victory |

| Model Number: | ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-7,ERNiCr-3 |

| Certification: | CE,ROHS,ISO 9001 |

| Place of Origin: | China |

| MOQ: | 15 |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 300 tons per month |

| Delivery Time: | 5-21 days |

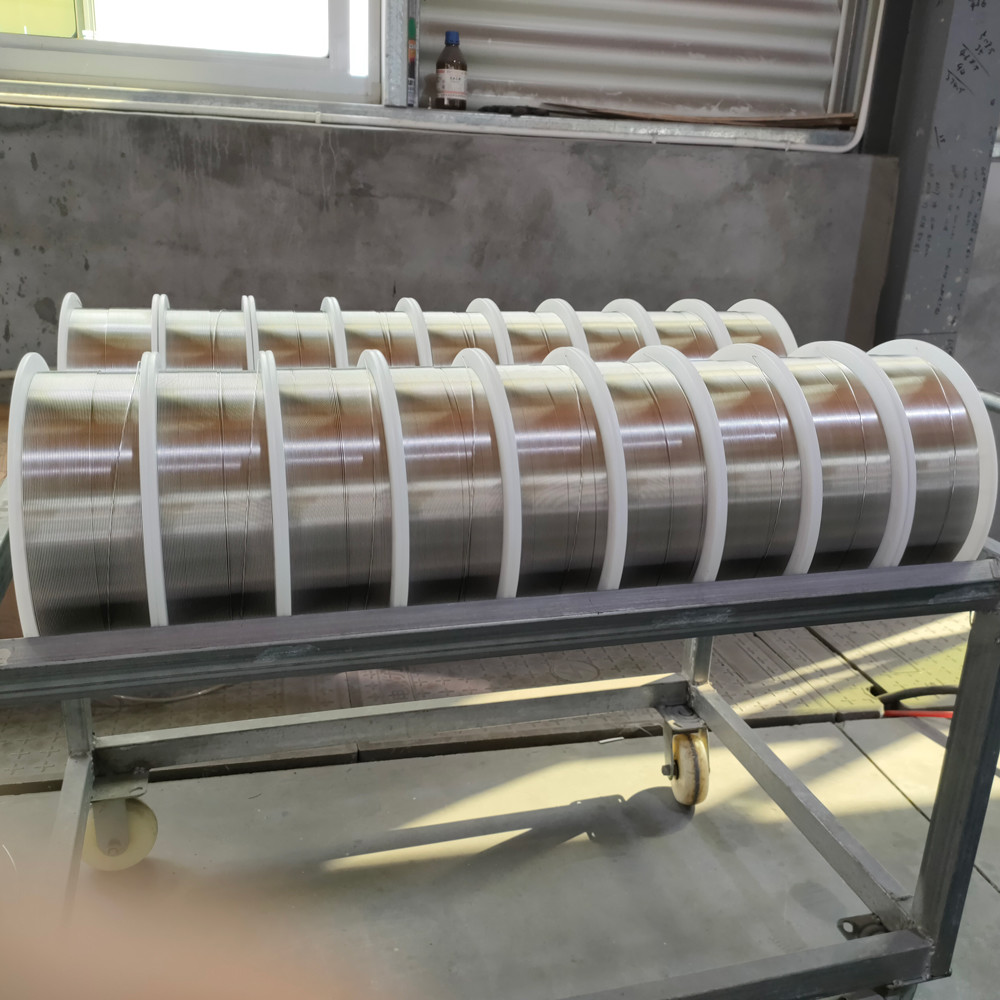

| Packaging Details: | Spool package with Carton box, Coil package with polybag |

| Material: | Ni, Mo, Cr |

| Elongation: | ≥22 % |

| Density: | 8.60 g/cm3 |

| Tensile strength Rm N/mm²: | ≥600 |

| Yieldstrength R P0. 2 N/mm²: | ≥360 |

| Melting point: | 1310-1360℃ |

| Certificates: | AWS A5.14 / ASME SFA A5.14 |

| Company Info. |

| Changzhou Victory Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Nickel welding wire is a type of metal welding material widely used in the field of welding, including various brands, such as ERNiCrMo-3, ERNiCrMo-4, ERNiCrMo-13, ERNiCrFe-7 and ERNiCr-3. Each grade of nickel wire has a unique alloy composition and welding properties suitable for different welding applications.

ERNiCrMo-3 is a high-alloy nickel welding wire with good corrosion resistance and high temperature stability. It is commonly used to weld high-alloy steel and nickel alloys in the chemical, petroleum and petrochemical industries.

ERNiCrMo-4 is a nickel-based alloy welding wire with excellent corrosion resistance and high temperature performance. It is suitable for welding stainless steel and nickel-based alloys and is commonly used in the chemical, marine engineering and nuclear industries.

ERNiCrMo-13 is a high-alloy nickel welding wire that performs well in welding corrosion-resistant alloys, high-temperature alloys and acid-resistant stainless steel, and can meet the requirements of harsh working environments.

ERNiCrFe-7 is a nickel-iron-based alloy welding wire, suitable for welding stainless steel, alloy steel and high-temperature alloys, with good corrosion resistance and high temperature performance.

| C | Si | Mn | Cr | P | Ni |

| ≤0.01 | ≤0.2 | ≤0.5 | 22.0-24.0 | ≤0.015 | Rem |

| Al | Mo | Fe | Cu | S | Co |

| 0.10-0.40 | 15.0-16.50 | ≤0.5 | ≤0.1 | <0.01 | <0.20 |

| Typical Welding Parameters | |||||

| Diameter | Process | Volt | Amps (flat) | Amps (V/OH) | |

| inch | (mm) | ||||

| 0.035 | 0.9 | GMAW | 26-29 | 150-190 | Spray Transfer 100% Argon |

| 0.045 | 1.2 | GMAW | 28-32 | 180-220 | Spray Transfer 100% Argon |

| 1/16 | 1.6 | GMAW | 29-33 | 200-250 | Spray Transfer 100% Argon |

| 1/16 | 1.6 | GTAW | 14-18 | 90-130 | 100% Argon |

| 3/32 | 2.4 | GTAW | 15-20 | 120-175 | 100% Argon |

| 1/8 | 3.17 | GTAW | 15-20 | 150-220 | 100% Argon |

| Tensile Strength | 109 Ksi | 790 MPA |

| Yield Strength | 68 Ksi | 470 MPA |

| Elongation | 40-45% | |

| Density g/cm3 | 8.60 g/cm3 | |

| Melting Point ℃ | 1300-1360℃ | |

| Coefficient of Expansion. 21-93 Co, μm/m * Co | 11.90 |

|  |

|