| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Polished Aluminium Profile |

|---|---|

| Place of Origin: | Guangdong, China (Mainland) |

| Brand Name: | Guangdong, China (Mainland) |

| Certification: | ISO9001:2000,ISO14001:2004 |

| Model Number: | customize |

| MOQ: | customize |

| Price: | negotiation |

| Packaging Details: | protective film for each piece, then each bundle in Kraft paper.or according to customer request |

| Delivery Time: | Within 15-25 days after receive deposit and and moulds are passed. |

| Payment Terms: | L/C, D/A, T/T, , MoneyGram |

| Supply Ability: | 6000 tons per month |

| Material: | Aluminum Alloy 6063,6063A,6060,6061 |

| Temper: | T4, T5, T52, T6, Etc |

| Thinckness: | 1.0/1.1/1.2/1.4 |

| Finish: | Polish |

| Length: | Based On Demand |

| Application: | Aluminum Building;aluminum Foil Building Construction Material |

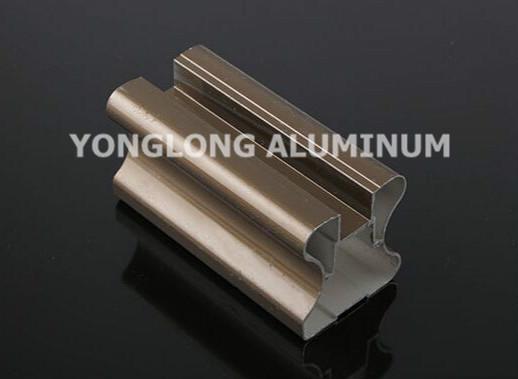

•• 6063 6061 Polished Extruded Aluminum Profiles With Different

Surface Processing ••

♦ Photos :

♦ Specification :

| Description | 6063 6061 Polished Extruded Aluminum Profiles With Different Surface Processing |

| Material | Aluminum Alloy 6063, 6061 |

| Material Thickness(t) | t=1.0 / 1.2 / 1.4 |

| Annealing Treatment | T5,T6 |

| Surface Treatment | Polish , etc. and depend on customer’s demand. |

| Color | Green, Grey, Black, White, (RAL series)etc. |

| Length | Normal length=6m or in customer's order |

| Shape | Square, Round, Flat, Oval, and according to customer's drawing. |

| Usage |

|

| Advantages/Features | Providing colorful products with various mechanical performances to adapt all kinds of architectural styles |

| Package | 1. Pearl cotton foam for each aluminum profile ; |

♦ Features :

♦ Corporate Introduction :

♦ FAQ :

Q – What is the average lead time for pre production samples?

A – Our average lead time is normally 7 days for making new samples and 7 days for testing , totally need about 14days.

Q – What is the average lead time for mass production?

A – Our average lead time is delivery within 20-30 days after receive deposit and and moulds/samples are passed.

Q – What is CAD?

A – CAD stands for “computer assisted design” and it is a 3-D

program that is used by our clients to provide our technicians with

a three-dimensional example of the custom shape that they want made

at GUANGDONG YONGLONG ALUMINUM.

Q – What is a die?

A – A die is a tool that is used to help forge a custom shape during the extrusion process. The die is made from durable steel so that it can be used again and again to fill the client’s order.

Q – What does extrusion mean?

A – Extrusion is the process that is used to create custom shapes from raw aluminum materials according to a client’s specifications. The raw materials are heated and are then forced through a die to create the desired shape using extreme pressure.

Q – What is powder-coating?

A – This is another type of chemical finishing that can be used to protect aluminum extrusion materials once they are completed. It is also used to create a certain desired look, color or texture that’s thicker than a paint finish, and yet also more durable. It is however, more expensive. Powder-coating is achieved by mixing finely ground color powder with resins and other chemical-based additives in order to achieve the desired finish.

Welcome to visit our company !

Choose us & contact us !

|