| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Thermal Spray Wire |

|---|---|

| Brand Name: | Victory |

| Model Number: | HC276 |

| Place of Origin: | China |

| MOQ: | 5 Kg |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 300 tons per month |

| Delivery Time: | 5-21 days |

| Packaging Details: | Spool package with Carton box, Coil package with polybag |

| Certification: | CE,ROHS,ISO 9001 |

| Price: | Negotiable |

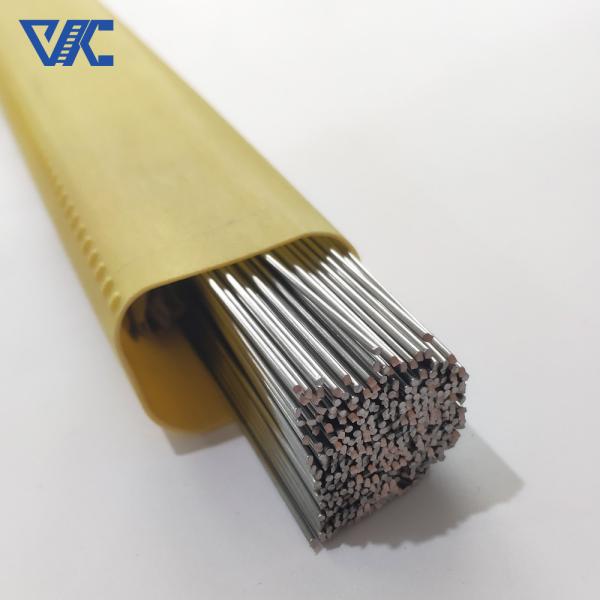

| Product name: | Thermal spray wire |

| Grade: | HC276 |

| Material: | Ni Fe Cr Mo |

| Bonding Strength: | 48.26 N/mm2 |

| Deposit Rate: | 10 lbs/hr/100A |

| Coating Hardness: | HRC 30-35 |

| Density: | 8.89g/cm3 |

| Melting point: | 1325-1370°C |

| Application: | Petrochemical equipment |

Introduction:

HC276 thermal spray wire, also known as Hastelloy C-276 thermal spray wire, is a high-performance corrosion-resistant alloy wire. It is composed of nickel, molybdenum, chromium, iron and other elements, and has excellent corrosion resistance and excellent mechanical properties.

HC276 thermal spray wire has a good balance in chemical composition and can resist the erosion of strong acids, strong alkali, salt solutions and oxidizing media. It is widely used in chemical, petroleum, pharmaceutical and other fields to provide reliable corrosion protection for equipment and components.

In addition, HC276 thermal spray wire also has excellent mechanical properties. It has high tensile strength, toughness and resistance to stress corrosion cracking, and remains stable in high temperatures and corrosive environments. This makes it ideal for applications requiring high strength and durability.

Thermal spray wire

| Item | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | HC-276 | Cr20Ni80 | K500 |

| C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.02 | ≤0.08 | ≤0.25 |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.0 | ≤0.06 | ≤1.5 |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 | ≤0.01 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.08 | 0.75-1.6 | ≤0.5 |

| Cr | 21.5-23 | ≤0.2 | 42-46 | - | 14.5-16 | 20-23 | - |

| Ni | Rest | Rest | Rest | 65-67 | Rest | Rest | Rest |

| Cu | - | - | - | Rest | - | - | 27-33 |

| Mo | 8.5-10 | - | - | - | 15-17 | - | - |

| Ti | ≤0.4 | 0.4-1 | 0.3-1.0 | 2.0-3.0 | - | - | 0.35-0.85 |

| Al | ≤0.4 | 4--5 | - | ≤0.5 | - | - | 2.3-3.15 |

| Fe | ≤1.0 | - | ≤0.5 | ≤1.0 | 4.0-7.0 | - | ≤1.0 |

| Nb | 3.5-4.15 | - | - | - | - | ≤1.0 | - |

| Co | - | - | - | - | - | - | - |

| V | - | - | - | - | ≤0.35 | - | - |

| W | - | - | - | - | 3.0-4.5 | - | - |

| Impurities | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 |

Feature:

Application:

Size range Wire: 0.12 to 8.0 mm.

|  |

Q&A:

What are the advantages of HC276 thermal spray wire over other

spray materials in the oil and gas industry?

HC276 thermal spray wire has excellent corrosion resistance, high

temperature stability and resistance to stress corrosion cracking,

making it suitable for highly corrosive and high temperature

environments in the oil and gas industry.

What are the specific applications of HC276 thermal spray wire in

petrochemical equipment?

HC276 thermal spray wire is often used in the manufacture of

petrochemical equipment, such as reactors, distillation towers,

heat exchangers and storage tanks. It provides corrosion

resistance, high temperature stability and protection against

stress corrosion cracking.

How does HC276 thermal spray wire cope with corrosion and high

temperature issues in the oil and gas industry?

HC276 thermal spray wire has excellent corrosion resistance and

high temperature stability, which can provide corrosion resistance

and high temperature stability protection in the oil and gas

industry, extending the service life of equipment and pipelines.

|