| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Titanium Electrode |

|---|---|

| Brand Name: | Changsheng |

| Model Number: | ASTM |

| Certification: | ISO 9001;2015 |

| Place of Origin: | China |

| MOQ: | 10pc |

| Price: | 100usd/set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000T/MONTH |

| Delivery Time: | 10-15days |

| Packaging Details: | packed with export wooden case |

| Shape: | Rod |

| Substrate: | Gr1 titanium ribbon |

| Coating: | Ir-Ta Ru-Ir Coating |

| Lifetime: | Available for 50,100 years |

| Height: | 700mm |

| Felt Thickness: | 0.25~5.0mm |

| Coating Thickness: | 4-6um as your requried |

| Another Name: | DSE(Dimensionally Stable Electrode |

| Electrode Efficiency: | ≥ 90% |

| Durability: | Long-lasting |

| Wire Diameter: | 0.15-0.20mm is commonly used |

| Pt Coating Thickness: | 0.5μm - 15 μm |

| Conductivity: | Good |

| Length: | <=2000mm |

| Coating Material: | Platinum precious metal |

| Company Info. |

| Baoji City Changsheng Titanium Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Description

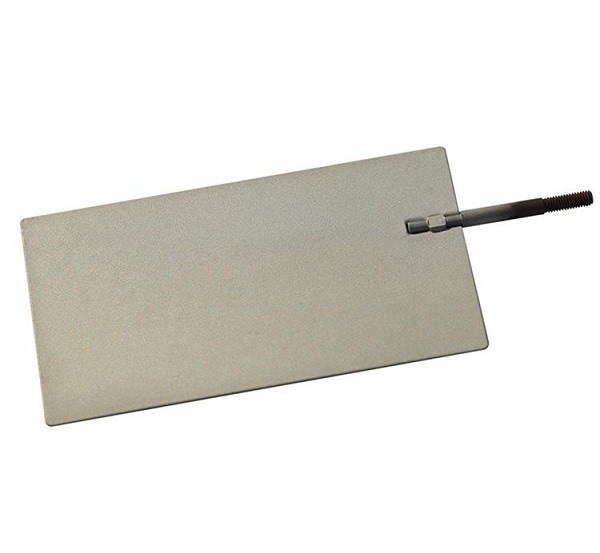

Titanium Plate Anode is widely used in various industrial processes

such as electroplating, electrolysis, and electrochemical reactions.

Made from high-purity titanium, it offers excellent corrosion resistance, long service life, and high current efficiency. Titanium anodes are suitable for use in both acidic and alkaline environments and can be customised to meet specific current density and

dimensional requirements.

Compared with other anode materials, the Titanium Coated Plate Anode provides superior performance and extended lifespan, making it an ideal choice for demanding electrochemical applications.

| Grade | N (%) | C (%) | H (%) | Fe (%) | O (%) | Ti (%) |

|---|---|---|---|---|---|---|

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Balance |

| Gr2 | 0.03 | 0.05 | 0.015 | 0.30 | 0.25 | Balance |

| Coating Type | Thickness (μm) |

|---|---|

| Platinum | 0.5 / 1.0 |

| Mixed Iridium & Platinum | 0.5 / 1.0 |

| Mixed Ruthenium & Iridium | 6–8 |

| Mixed Iridium & Tantalum | 6–8 |

Coating: Mixed Ruthenium and Iridium

Chlorine Evolution Potential: < 1.13 V

Polarizability: ≤ 40 mV

Accelerated Life: ≥ 3000 min (at 1000 A/m²)

Anode Strengthening Weight Loss: ≤ 10 mg

Suitable Environment: Chloride-containing solution, pH ≤ 7

| Coating Load (g/m²) | Estimated Life (hours) |

|---|---|

| 8 | > 6,000 |

| 10 | > 8,000 |

| 12 | > 10,000 |

| 15 | > 12,000 |

| 20 | > 15,000 |

Current Density: < 600 A/m²

Operating Temperature: 40–60 °C

Chlorine Concentration: 30–50 g/L

Polarity Reversal: Suitable

Reversal Frequency: Every 2–4 hours

| Size (mm) | Quantity / Set |

|---|---|

| 63.5 × 150 | 13 pcs |

| 64 × 110 | 7 pcs |

| 80 × 120 | 1 pc |

| 30 × 183 | 7 pcs |

| 80 × 185 | 7 pcs |

Electroplating: Suitable for gold, silver, copper, and other metal plating.

Chlor-Alkali Production: Used in the manufacture of sodium hydroxide and chlorine.

Desalination: Applied in water desalination systems for salt removal.

Seawater Purification: Used to purify seawater for industrial and potable use.

Cathodic Protection: Protects ships, offshore platforms, and submerged structures from corrosion.

Metal Recovery: Recovers valuable metals from industrial waste streams.

Hydrogen Production: Utilised in electrolysis for hydrogen generation.

|