| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Plastic Blow Molding Machine |

|---|---|

| Brand Name: | TONGDA |

| Model Number: | TDB-50F |

| Certification: | CE, ISO9001 |

| Place of Origin: | JIANGSU, CHINA |

| MOQ: | 1SET |

| Price: | $60,000.00 - $70,000.00/Sets |

| Payment Terms: | T/T, L/C, D/P, West Union |

| Supply Ability: | 800sets/year extrusion blow molding machine |

| Delivery Time: | 50-60 working days |

| Packaging Details: | PE film, PE bag, Wooden Cases, Wooden Pallet, etc. for our extrusion blow molding machine and auxiliary equipments |

| Max. product volume: | 160L |

| Dry cycle: | 120 |

| Weight of machine: | 22000 |

| Size of machine: | 5.8*2.9*4.4 |

| Capacity of accumulator head: | 18 |

| Clamping force: | 740 |

Plastic Blowing Making Machine Plastic Drum Extrusion Blow Molding Machine

Product Description

Our TDB-160F model extrusion blow molding machine, is one of the hot sale model machines. Over 100sets/year machine will be delivered to customers' factory to help them earn profit or saving the package cost(for customers who start to product the packages themselves). It is with wide application

Technical Parameters of our TDB-160F Extrusion Blow Molding Machine

MODEL | Units | TDB-160F | Remarks: we will customize the most suitable extrusion blow molding

machine for you according to your requirements |

Max. Product volume | L | 160 | |

Output of HDPE | kg/h | 230 | |

Clamping force | kn | 740 | |

| Accumulator head Capacity | mm | 100, 28:1 | |

Platen Distance | mm | 500-1400 | |

Screw Motor Power | KW | 75 |

Product Details of our TDB-160F Extrusion Blow Molding Machine

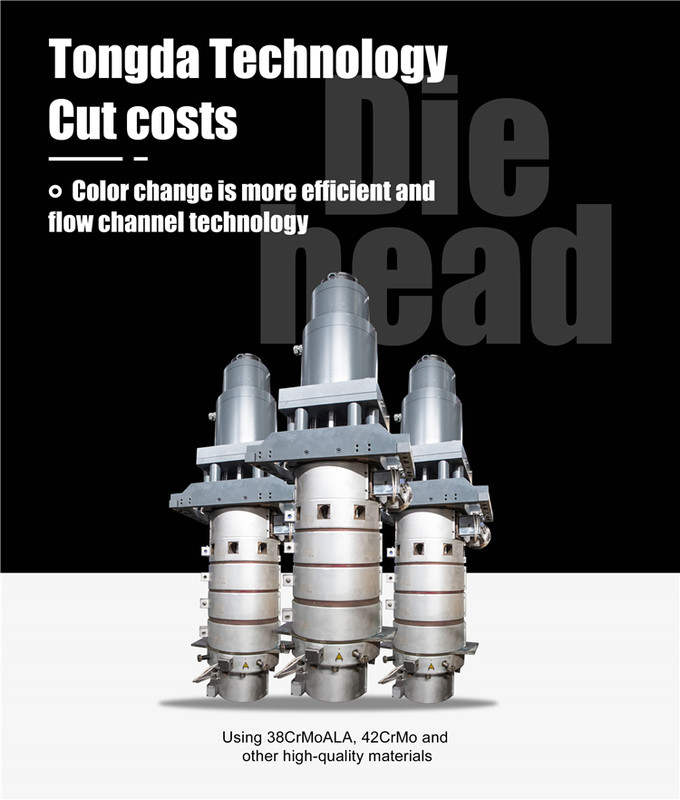

Die head: Excellent flow channel technology and precise machining accuracy, make the color change and material change more efficient. From dark to white, normally can be completed within 3hours. Much quicker than other suppliers. Save cost for you if you need to produce different color products.

Bottom Blowing Unit, with high precission of component assembly, can also be equipped with down seal device

Upper parison sealing device, stable and reliable

Company Information

Suzhou Tongda Machinery have more than 20,000m2 factory buildings and other facilicities and a new intelligent manufacturing factory with 55,000m2 area. The I phase 20,000m2 area factory will be put into use in June, 2022. And on May 19th, 2022, we just held the II phase intelligent manufacturing base groundbreaking ceremony.

Service Network

Our Machinery has been keeping good cooperative relationship with customers since our establishing.

The satisfaction of our customers are the pursuit of every member of Tongda,The only way we service in the competitive market is to help our customers to full fill their requirement.

TONGDA sales consultant

1. We can provide comprehensive and professional Suggestions on

equipment selection.

2. Energy consumption calculation and investment income analysis

can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product

optimization Suggestions.

4. Extrusion plastic bottle blow molding machine has remote

maintenance function

Advantages of TONGDA tech teams

1. 800 sets of customized requirements per year enable us to have

rich experience across multiple industries.

2. Customize equipment models according to customer product

characteristics.

3. Project responsibility system, closed-loop team cooperation

between the design team and the process team, adjustment of the

team, and joint creation of equipment that users are satisfied

with.

4. Engineers can study abroad or participate in technical function

training of the industry to master the latest information and

technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior

technical personnel composed of the construction team, can build

cable bridge, installation of a complete set of equipment.

Advantages of TONGDA after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of

auxiliary equipment.

5. A free 2-day training course will be provided to customers every

year.

6. Special processing equipment to produce after-sales accessories

to ensure rapid response to user needs.

|