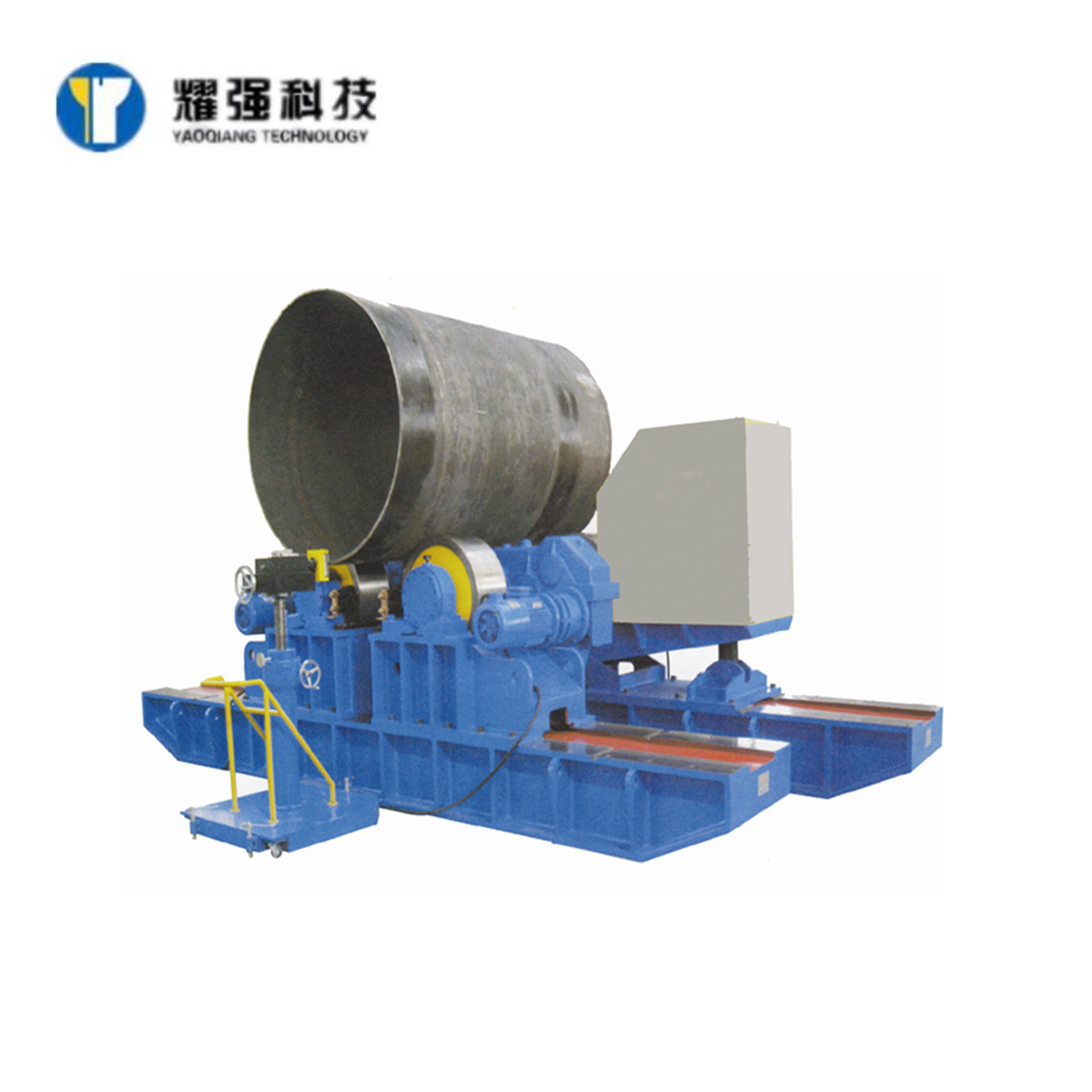

Features:

1, HGZ roller frame mainly includes active wheel frame, electric

control system and etc.

2, Active roller frame base has two sets roller device which can

turn a certain angle. Two sets of wheel device can rotate around

its center axis angle, so they can automatically adjust the along

with the workpiece size, to ensure smooth continuous when rotating.

3, Active roller is equipped with a set of drive device, includes

the drive motor, reducer, coupling, coupling shaft and other

components. Using domestic AC motor drive motor is driven by the

first -stage worm gear drive with two roller device mandrel coaxial

worm reducer, and through two sets of gears to drive the wheel

rotates. It can balance the distribution of friction while

workpiece rotates, the rotation of the workpiece smoothly and drive

capability increased. This strengthens workpiece quality. Reducer

lubrication is oil-immersed fully enclosed, to eliminate weld

spatter, slag, dust and foreign invasion, to obtain

maintenance-free and long life characteristics.

4, Electrical control system consists of electrical control box and

hand control box components.

Electric control box is made by a variable speed system,

contactors, buttons and other components, mainly low-voltage

electrical components using well-known brands such as Siemens, with

reliable performance, easy maintenance.

Frequency speed control system is featured with low-noise,

high-performance, multi-function drive, with wide range, constant

torque speed characteristics, steady speed adjustment, no torque

ripple. The control signal using analog control, speed display is

high-precision digital display, with high overall stability, strong

anti-jamming capability. With electric control boxes and hand

control box, user can do commissioning and operation for each

agency, both short and remote range. Flexible for operation, safe

and convenient.

On the electrical control box are: Power indicator, power switch.

On the manual control box panel are: Wheel speed adjustment knob

and digital speed display, forward and reverse button and alarm

reset.

| type | max load weight(kg) | metallic wheel | rubber wheel | cylinder D | roller linear speed(m/h) | motor power | way of setting |

| | | | | | | | |

| HGZ-05 | 5000 | 244 | 20 | 250 | 100 | 250 | 2300 | 6-60 | 0.75 | / | AC frequency conversion

stepless speed regulation |

| HGZ-10 | 10000 | 294 | 25 | 300 | 120 | 320 | 2800 | 1.1 | / |

| HGZ-20 | 20000 | 344 | 30 | 350 | 120 | 500 | 3500 | 1.5 | / |

| HGZ-30 | 30000 | 344 | 30 | 350 | 120 | 500 | 4000 | 2.2 | / |

| HGZ-40 | 40000 | 394 | 40 | 400 | 120 | 600 | 4200 | 3 | 2*1.5 |

| HGZ-50 | 50000 | 394 | 40 | 400 | 120 | 600 | 4500 | 3 | 2*1.5 |

| HGZ-60 | 60000 | 444 | 50 | 450 | 120 | 750 | 4800 | 4 | 2*2.2 |

| HGZ-80 | 80000 | 494 | 60 | 500 | 120 | 850 | 5000 | 4 | 2*3 |

| HGZ-100 | 100000 | 494 | 80 | 500 | 120 | 1000 | 5500 | 5.5 | 2*3 |

| HGZ-150 | 150000 | / | / | 600 | 280 | 1100 | 6000 | 7.5 | 2*4 |

| HGZ-250 | 250000 | / | / | 700 | 300 | 1200 | 7000 | 11 | 2*5.5 |

FAQ:

Q1: I knew nothing about this machine, how am i know this machine

will meet my working needs?

Please tell us your workpiece size or show specific drawings, we

will give you professional solutions.

Q2: When I got this machine, but I don't know how to use it. What

should I do?

We provide overseas service and English manual, after installation,

if any problems happen, we offer the remote video guidance and

charging overseas service.

Q3: If some problems happen to this machine during warranty period,

what should I do?

Contact us directly, we will supply free parts during machine

warranty period. While we also supply free life long after-sales

service.

Q4: If i want visit your factory, how can i get?

Company address:39#, Liandong U business park, Wuxi city, Jiangsu,

China

Factory address:Xinhong Industrial Park, Dongtai Yancheng City,

Jiangsu, China

1), Visa: if u need get a government visa, pls pay 20%(at least)

prepayment for new customer. Wuxi government regulations. Thanks

for support.

2), By train: Wuxi station. By air: Wuxi Shuofang Airport. We will

drive u to our factory. 180km between Wuxi and Yancheng city.

Q5: Why your sales office at Wuxi, but your factory located at

Yancheng?

10 years ago. In response to the Yancheng government investment

invitation, our leader moved the factory from Wuxi to Yancheng,

purchased 15,000 square meters of land and built factories. In

order to reduce production costs and sustainable development.

Tips: At present, the Jiangsu government is building the provincial

high-speed railway. It is expected that Yancheng will open the

subway in 2023.