| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | PCB Assembly Service |

|---|---|

| Brand Name: | CKS |

| Model Number: | CKS-Customized |

| Certification: | ISO9001 |

| Place of Origin: | CHINA |

| MOQ: | 1 Piece/Pieces |

| Price: | USD 2.41-4.6 |

| Payment Terms: | L/C, Western Union, MoneyGram, T/T |

| Supply Ability: | 400000 Pieces per Month |

| Delivery Time: | 80-110 days |

| Packaging Details: | 33CM*20CM*10.5CM |

| Copper thickness: | 0.25 Oz -12 Oz |

| Min. line width: | 3mi,0.2mm |

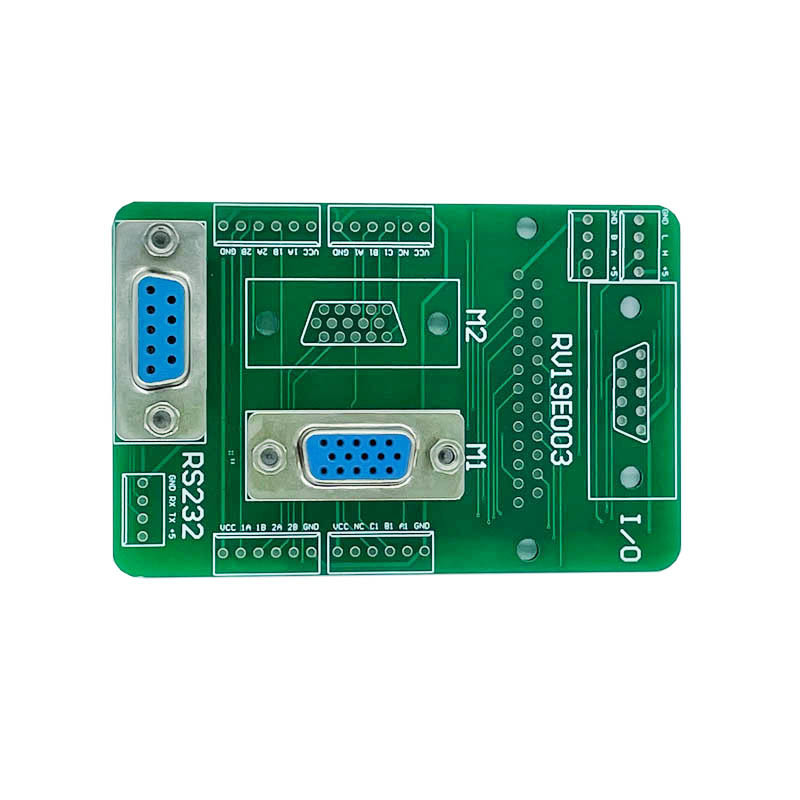

| Product name: | Engineering Design Services High Quality Pcb Assembly Pcb,PCBA OEM Audio Amplifier Board SMD PCB Assembly Services |

| Service: | professional engineer |

| Solder mask color: | White Black Yellow Green Red |

| Solder mask: | Green |

Professional Custom Rohs Pcba Pcb Assembly Service Printed Circuit Board

1. Support ODM project

2. Strong supply capacity (4 million points per day for SMT, 1 million points per day for DIP, and 20,000 sets per day for finished products)

3. BGA, dense-foot chip technology

4. provide lead or lead-free process as customer requirements

5. keep the customer information confidential

Our advantage

| Items | PCBA capacity |

| Product name | SMT circuit board manufacturer custom electronic assembly pcb pcba |

| Assembly details | SMT and Thru-hole, ISO SMT and DIP lines |

| Testing on products | Testing jig/mold , X-ray Inspection, AOI Test, Functional test |

| Quantity | Min quantity : 1pcs. Prototype, small order, mass order, all OK |

| Files needed | PCB : Gerber files(CAM, PCB, PCBDOC) |

| Components : Bill of Materials(BOM list) | |

| Assembly : Pick-N-Place file | |

| PCB Panel Size | Min size : 0.25*0.25 inches(6*6mm) |

| Max size : 1200*600mm | |

| Components details | Passive Down to 0201 size |

| BGA and VFBGA | |

| Leadless Chip Carriers/CSP | |

| Double-sided SMT Assembly | |

| Fine BGA Pitch to 0.2mm(8mil) | |

| BGA Repair and Reball | |

| Part Removal and Replacement | |

| Component package | Cut Tape, Tube, Reels, Loose Parts |

| PCB+ assembly process | Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity |

SMT workshop

DIP workshop

Product usage

COMPANY MEMBER

|