| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Custom Injection Mold |

|---|---|

| Brand Name: | LiQi |

| Model Number: | OEM |

| Certification: | ISO,GE |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 100000 Piece/Pieces per Month |

| Delivery Time: | 35-50 days |

| Packaging Details: | Wooden case |

| Mould core material: | P20/ H718 /S136 |

| Shape Mode: | Die Casting |

| Design: | FUTABA,LKM,HASCO,DME |

| Cavity: | Multi |

| Runner System: | Hot runner/ Cold runner |

| Mold Life: | 250000-500000shots |

| Company Info. |

| JinJiang LiQi Mould Co., Ltd |

| View Contact Details |

| Product List |

Six Cavities Custom Injection Mold High Strength Insert Plastic

Custom Injection Mold or die are the common terms used to describe the tool used to produce plastic parts in Custom Injection Molding.

Since Custom Injection Molds have been expensive to manufacture, they were usually only used in mass production where thousands of parts were being produced. Typical Custom Injection Molds are constructed from hardened steel, pre-hardened steel, aluminium, and/or beryllium-copper alloy. The choice of material to build a Custom Injection Mold from is primarily one of economics; in general, steel Custom Injection Molds cost more to construct, but their longer lifespan offsets the higher initial cost over a higher number of parts made before wearing out. Pre-hardened steel Custom Injection Molds are less wear-resistant and are used for lower volume requirements or larger components; their typical steel hardness is 38–45 on the Rockwell-C scale. Hardened steel Custom Injection Molds are heat treated after machining; these are by far superior in terms of wear resistance and lifespan. Typical hardness ranges between 50 and 60 Rockwell-C (HRC). Aluminium Custom Injection Molds can cost substantially less, and when designed and machined with modern computerised equipment can be economical for Custom Injection Molding tens or even hundreds of thousands of parts. Beryllium copper is used in areas of the Custom Injection Mold that require fast heat removal or areas that see the most shear heat generated.[16]: 176 The Custom Injection Molds can be manufactured either by CNC machining or by using electrical discharge machining processes.

| Product Description | World Standard Custom Injection Mold Plastic Molding Case Type |

| Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Standard: | ISO9001:2008 |

| Other materials: | Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper...Metal...etc. |

| Quality: | RoSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your 2D, 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

| Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

| Export Country: | Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.: |

| Experience: | 13 years experience in plastic injection mold making and plastic prouducts produce. |

| To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. |

| Mould Base: | Hasco Standard, European Standard, World Standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

| Surface Finish: | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

| Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

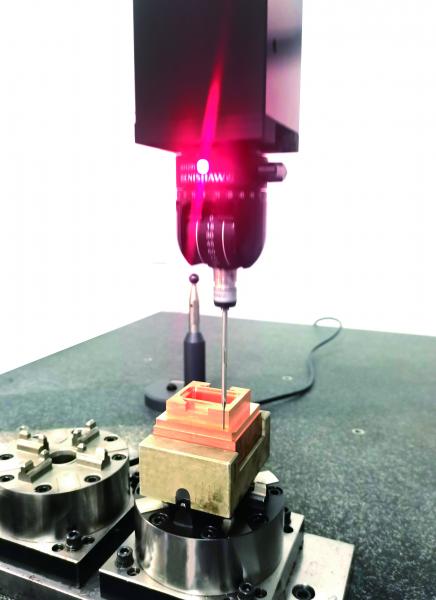

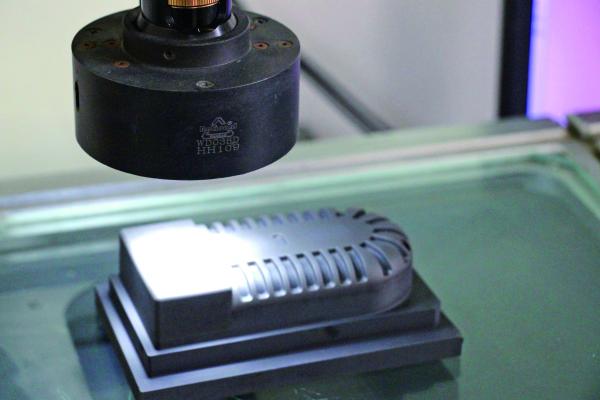

| Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

Equipments:

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available.

|