| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Automatic Capping Machine |

|---|---|

| Brand Name: | Jinwang |

| Model Number: | FXG-1D |

| Certification: | CE,CO,ISO |

| Place of Origin: | made in China |

| MOQ: | 1 set |

| Price: | negotiation |

| Supply Ability: | 1 Osets per month |

| Packaging Details: | wooden cases |

| Delivery Time: | 15-90 work days |

| Payment Terms: | L/C, T/T |

| Model: | FXG-1D |

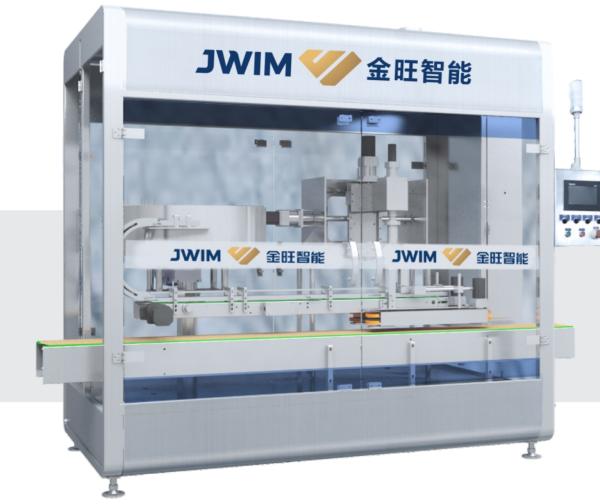

| Name: | 10L-30L Bucket Automatic Capping Machine 1/2 Capping Heads |

| Power supply: | AC220V/380V; 50/60 Hz (may customized) |

| Power: | 4.1KW |

| Qualification Rate: | ≥99.9% (Bottle center deviation < 1 mm, bottle month height deviation < 1 mm) |

| Bottle Feeding direction: | From left to right |

| Production capacity: | 2500 / 4000 bottles/hour |

| Machine weight: | ~1200Kg |

| Company Info. |

| Jiangsu Jinwang Intelligent Sci-Tech Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

10L-30L Bucket Automatic Capping Machine 1/2 Capping Heads

This machine is specially designed for 1-5L lubricant products. It

adopts CNC single-track electric single-head grab-type tracking

screw cap.

France Schneider servo system, France Schneider PLC programmable

control, touch screen man-machine interface operation, all

parameters are evenly modified in the touch screen. Automatic

gripping and capping are completed by the servo motor, and the

movement is precise and the speed is fast. The servo system +

torque module controls the capping head, and the cap tightness is

freely set.

When the capping head is working, the set torque is automatically

stopped. Electric rotary type capping machine adopts double

photoelectric screening for positive and negative cover, and the

screening pass rate is 100%.

The whole machine is made of 304 stainless steel material.

Technical Parameters

| 1 | Capacity | ≤2500BPH~4000BPH |

| 2 | Qualification Rate | ≥99.9% |

| 3 | Applicable Drum | Min.:140×60×230mm Max.:260×145×330mm (Bottle center deviation < 1 mm, bottle month height deviation < 1 mm) |

| 4 | Cap Size | Φ25-70mm |

| 5 | Air Pressure | 0.6-0.8 Mpa |

| 6 | Power Source | ~380V 50Hz 4.1KW |

| 7 | Weight | ~1200Kg |

| 8 | External Dimension | 1995×1380×2237mm(L×W×H) |

Advanced Features

1. Save labor: Conventional capping machine shakes the bottle's mouth. Contaminating the bottle body and the conveyor belt requires one person to clean the bottle body and the bottle mouth. The swing arm capping machine does not shake the liquid, eliminating the need to manually wipe the bottle body and the bottle mouth.

2. Quality Improvement: This equipment is the latest development of

our company. It does not stop at the time of capping, no material

shakes out of the bottle mouth, does not contaminate the bottle

body and the conveyor belt, has no influence on the aluminum foil

sealing, and improves product quality.

3. Adopting the imported motion module controller + motion module

control follow-up capping method, the production capacity: ≤2500

bottles/hour.

4. Adopt servo motor control the bottle separating belt, and position the drum more precisely, which can ensure a high cap qualification rate.

5. No consumable parts: Replacement specifications only need to replace caps with different specifications and can be replaced in 10 minutes.

6. Fast Change Over. Electric adjustment in touch screen by fine-tuning. Mechanical adjustment is achieved by hand-cranked screw and scale ruler, which is quick and convenient.

7. The whole machine adopts an imported system France Schneider opponents, speed is faster and more stable.

After-sales Service:

(1) Under stable voltage, the machines' quality that we sold will

be guaranteed for 2 year

(2) Long-time technology will be supplied.

(3) We can dispatch our engineer to your side for installing and

debugging machines. Engineer's round-trip tickets, accommodation,

and your side traveling fee will be charged by you. The engineer's

salary will be USD100.00/day/person.

We can also supply training processes for your engineers who come

to china, so you can fit and debug machines by yourself.

|