| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Reheater In Boiler |

|---|---|

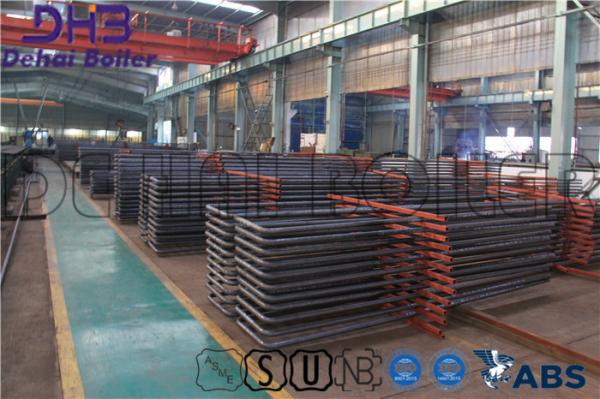

| Brand Name: | Dehai Boiler |

| Model Number: | Reheater |

| Certification: | ISO9001 , SGS , ABS , ASME |

| Place of Origin: | China |

| MOQ: | 10 Tons |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 800 Tons / Month |

| Delivery Time: | 45 Days |

| Packaging Details: | Seaworthy packing |

| Type: | Energy Saving |

| Technique: | Pipe Bending |

| Output: | Steam |

| Specialty: | Heat and Corrosion Resistant |

| Heat Treatment: | Included |

Radiant Superheater and Reheater for High Pressure Boiler Spare Parts Low temperature

Thermal power station

1. A thermal power station is a power station in which heat energy is converted to electric power. In most of the places in the world the turbine is steam-driven.

2. Water is heated, turns into steam and spins a steam turbine which drives an electrical generator. After it passes through the turbine, the steam is condensed in a condenser and recycled to where it was heated; this is known as a Rankine cycle.

3. The greatest variation in the design of thermal power stations is due to the different heat sources; fossil fuel dominates here, although nuclear heat energy and solar heat energy are also used.

4. Some prefer to use the term energy center because such facilities convert forms of heat energy into electrical energy.

5. Certain thermal power stations are also designed to produce heat energy for industrial purposes, or district heating, or desalination of water, in addition to generating electrical power.

Reheater Introduction

1. Power station furnaces may have a reheater section containing tubes heated by hot flue gases outside the tubes.

2. Exhaust steam from the high-pressure turbine is passed through these heated tubes to collect more energy before driving the intermediate and then low-pressure turbines.

Reheater Function

1. Therefore the number of reheat stages can not be many as the pressure drop will reduce efficiency of thermal cycle.The steam pipes and reheater coils are to be so designed to limit the drop to 2–3%.

2. The control valves in reheat steam path is not desirable.Systems using HP LP bypass require these valves to control steam flow during bypass operation.

3. The efficiency of the Reheat cycle can be improved by increasing the pressure and temperature of steam entering into the turbine. As the initial pressure increases the expansion ratio of the turbine also increases and the steam becomes quite wet at the end of expansion.

Main Advantage

The main advantage of reheat cycle is to reduce the specific consumption and consequently reduce the size of the boiler and other auxilaries for the same power.The reheat cycle is preffered for the high capacity above 100 MW plant.

Differences

| Type | Advantages | Disadvantages | Supporting method |

| Pendant-type | 1.Firm structural support | 1. Flow blockage by condensed steam 2. Needs slow restart to purge the water that accumulates in the bottom. | supported from above |

| Inverted-type | 1.Proper drainage of the condensed steam | 1. Lack the structural rigidity, especially in high speed gas flow | Supported from below |

| Horizontal -type | 1. Proper drainage 2. Good structural rigidity. | 1. They do not view the flam directly so they are mainly from the convective type | Usually supported in the vertical gas ducts parallel to the main furnace. |

Assemblying

100% RT Test

Squeezing

|