| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Through Hole Slip Ring |

|---|---|

| Brand Name: | CENO |

| Model Number: | ECN060-12P3-26P2-13P |

| Certification: | CE,RoHS,UL,ISO9001 |

| Place of Origin: | China |

| MOQ: | 1pcs |

| Price: | Negotiable |

| Payment Terms: | T/T,Paypal,Western Union |

| Supply Ability: | 5000pcs month |

| Delivery Time: | Off the shelf |

| Packaging Details: | Carton/Crate |

| Current: | 13*20A,12*15A,16*10A,10*10A |

| Rating voltage: | 380VAC/220VAC/24VDC |

| Electrical noise: | ≤15mΩ(50rpm) |

| Working speed: | 0~150rpm |

| Through bore size: | 60mm |

| Operating temperature: | -20~+80℃ |

| Company Info. |

| CENO Electronics Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

-20 to 80℃ Operating Temperature Through Hole Slip Rings Low Electrical Noise

Through hole slip rings .The main feature is the clear inner diameter through the center of the assembly allowing for the passage of fiber optics, air, fluid lines, optical paths or any other device that is required in the structure. The use of contact material using precious metals, torque is small, stable operation, long life, small resistance fluctuations, It can work on high temperature 80℃ and very low temperature -20℃.

Applications

Optional

Features

Parameter

| ECN060-12P3-26P2-13P Specification | Picture | |

| Current | 13*20A,12*15A,16*10A,10*10A |  |

| Voltage | 380VAC/220VAC/24VDC | |

| Electrical noise | ≤15mΩ(50rpm) | |

| Dielectric strength | ≥1500V@50Hz(power) ≥500V@50Hz(signal) | |

| Insulation resistance | 500MΩ@500VDC(power) 100MΩ@100VDC(signal) | |

| Operating speed | 0-150 rpm | |

| Contact material | Precious metals | |

| Operating temperature | -20~+80℃ | |

| Through bore size | 60mm | |

| IP protection grade | IP54 | |

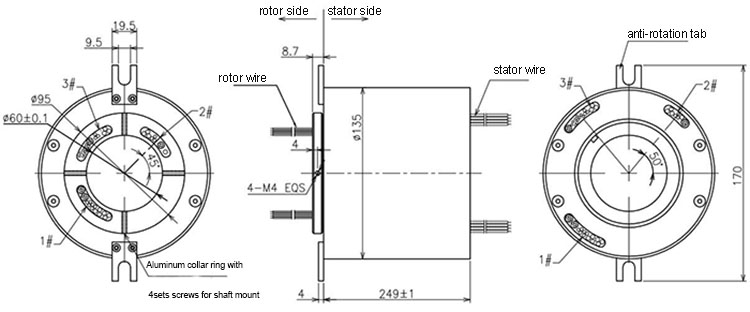

Outline drawing

Q: Do you offer hybrid design with electrical channel and fluid or

air channel combination?

Yes,CENO air/fluid rotary union and electrical slip ring can be

integrated together into one complete solution.The solution can for

fluid, power, signal, and data transfer. We offer both standard

assemblies and custom solutions to meet your exact requirements.

Welcome to consult us with your demands.

Q: How do we mount the hollow shaft slip ring on our machinery?

Hollow shaft mounting way

1) Position the slip ring in the desired location and equally tighten

both set screws to the shaft on each end of the union. Torque to 25

lb-in.

2) Route the wiring and make the necessary connections. Do not allow

the wiring to restrict free rotation of the slip ring.

3) Position a screw or dowel (not supplied) in the anti-rotation tab.

Flange mounting way

1) Align the mounting holes in the flange to mounting base and install

flat washers and thread forming screws (NOT SUPPLIED) for plastic.

Securely tighten screws.

2) Route the wiring and make the necessary connections. Do not allow

the wiring to restrict free rotation of the slip ring.

3) Position a screw or dowel (not supplied) in the anti-rotation tab.

CENO Advantage

Member in engineering team have more than 10 years experience in

slip ring's field.Operators work on critical procedure are all

qualified by internal training.

Why choose CENO

CENO is one technologically company in slip ring field who engages research and development,manufacturing and sales.We have advanced equipment and high precision test instruments to ensure products quality and reliable performance.Facility area covers 3000 square meters and located in China.

Honor

ISO9001,CE,RoHS,UL,Explosion-proof

Service CENO provides

Solution offerring for 360° rotation system.

Mass and customized production.

24 hours,7days consultant service.

Consult us with your requests for any 360° rotation system.We will

provide one stop service to you timely respond your inquiries.

Features

|