| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | PVC Pipe Extrusion Line |

|---|---|

| Brand Name: | LB |

| Model Number: | LB-32 |

| Certification: | CE ISO9001 |

| Place of Origin: | ZHANGJIAGANG, JIANGSU |

| MOQ: | 1 SET |

| Price: | USD/EUR |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 15 SETS PER MONTH |

| Delivery Time: | 30 WORKING DAYS |

| Packaging Details: | NORMAL PACKAGE |

| PIPE DIAMETER: | 75-250 |

| EXTRUDER'S POWER: | 55KW |

| COLOUR: | CUSTOMIZED |

| PIPE UMBERS: | DOUBLE PIPE |

| RAW MATERIAL: | PVC POWDER & ADDITIVES |

| APPLICATION: | WATER SUPPLY PIPE |

| Voltage: | 380V 50Hz or customized |

| Automatic grade: | Full-automatically |

| Screw design: | Twin screw and barrel |

| After-sales service provided: | Engineers available to service machinery overseas,Field installation,commissioning and training,Online support,Video technical support |

| Warranty: | 18 months |

| Inverter: | ABB |

| Color: | Customizable |

| Raw material: | PVC Powder |

| Motor: | Famous Brand |

| Contactor: | SCHNIDER |

| Screw and barrel: | Conical twin screw extruder |

| Screw diameter: | 65/132 |

| Pipe Application: | Water Supply |

| Packages: | Film and boxes |

| Payment: | T/T, L/C, Western Union |

| Delivery time: | 60 days |

| Company Info. |

| Zhangjiagang Langbo Machinery Co. Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

PVC Tube Making Machine, PVC Pipe Extruder, conical twin screw extruder

Short desciption

We provide a range of plastic pipe production lines, including 16-630mm PVC/UPVC pipe lines, 16-1200mm HDPE pipe lines, as well as lines for PP/PPR pipes, HDPE/PP/PVC double-wall corrugated pipes, and single-wall corrugated pipes. These lines can produce pipes for various applications such as water supply, drainage, gas supply, and conduit wiring. Specifically, the PVC pipe production line manufactures PVC pipes of different diameters and wall thicknesses, widely used in agricultural water supply, drainage, and electrical conduits.

Application

The UPVC pipes produced find extensive use in both industrial and daily scenarios, including electrical conduits, water supply pipes, sewage pipes, home decoration, chemical transportation, and gas distribution lines. They boast high strength and rigidity, structural integrity, excellent chemical resistance, durability, thermal stability, non-toxic safety, low maintenance needs, and cost-effectiveness.

Producting process

PVC powder + additives → Mixing → Spring feeding → Twin-screw extruder → Mould and calibrator → Vacuum forming machine → Haul-off machine → Cutting machine → Stacker.

Specifications:

| Model/data | Pipe diameter | Extruder model | Speed | Max capacity |

| LB-63 | 16-63mm | LB-51/105 | 1-10m/min | 120kg/h |

| LB-160 | 75-200mm | LB-65/132 | 1.5-5m/mmin | 260kg/h |

| LB-400 | 200-400mm | LB-80/156 | 0.5-1.5m/min | 400kg/h |

| LB-630 | 400-630mm | LB-92/188 | 0.1-0.8m/min | 650kg/h |

Product detail

Mixer

With specific design of mixer, the self-friction of raw materials is reduced. It is conducive to the efficiency of energy utilization. The Vacuum suction load with low noise and no-dust working situation.

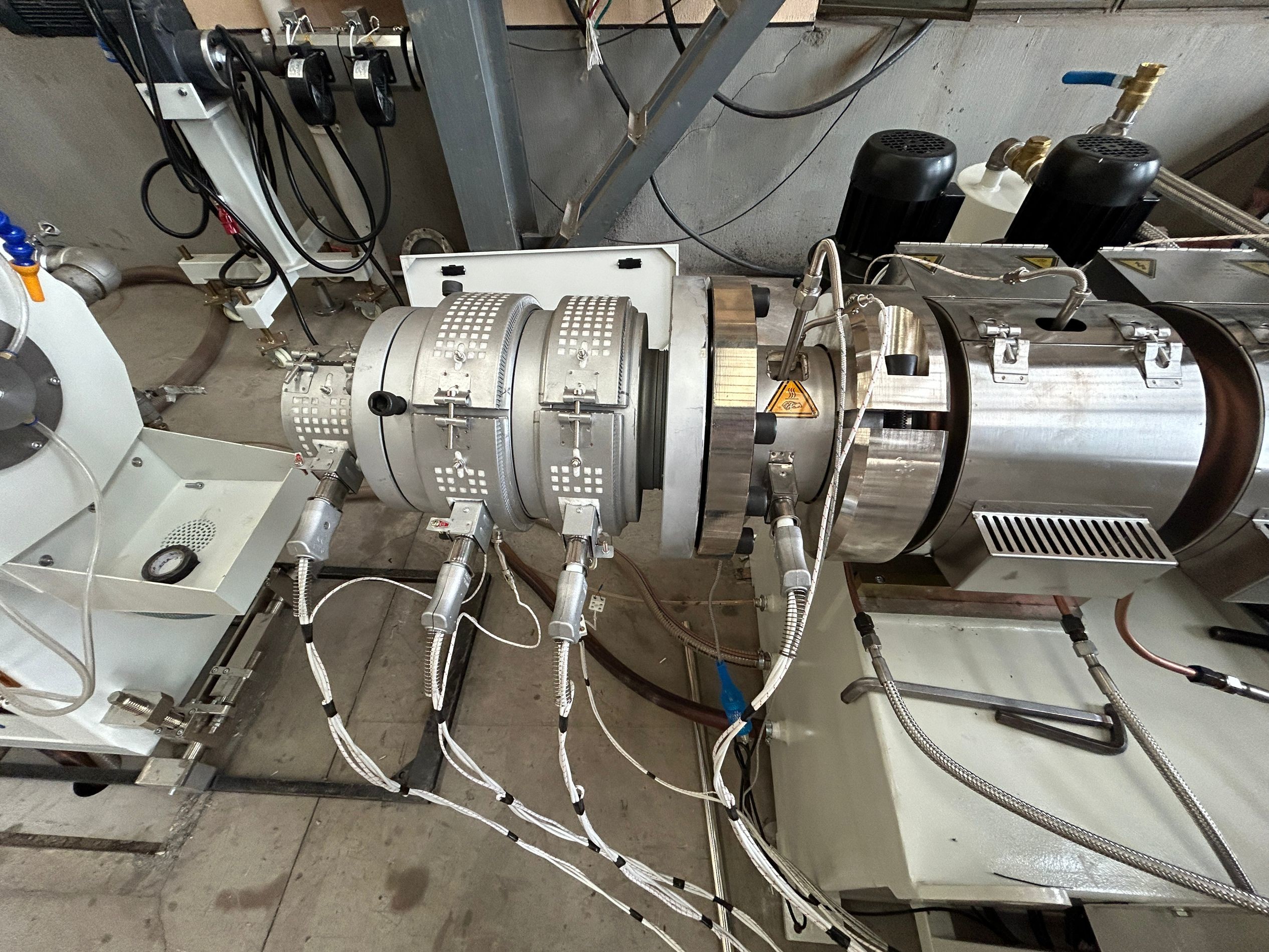

Twin screw extruder machine

The extruder are crafted with top brand components to ensure production stability, efficiency and machine durability. Our conical twin screw extruder design cater to the raw materials feature ensuring homogeneous mixture, better plastification and conveying efficiency.

Vacuum Calibration & Cooling

The vacuum calibration tank adopt two chamber structure: the vacuum calibration and cooling parts. Both of vacuum tank and spraying cooling tank adopt stainless 304 steel. The excellent vacuum system ensures precise sizing for pipes.

Haul-off Unit

The three caterpillar on the haul-off machine ensures produced pipe running stably and steady. The haul-off units can make tailored hauling model based on certain production requirement by adjusting the general control.

Cutting Unit

The high accuracy encoder ensures a precise and stable cutting length. With PLC control system, it can be cut by manual operation according to the specific application.

|