| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Liquid Packing Machine |

|---|---|

| Type: | Multi-Function Packaging Machine, Packing Machine,Packaging Machine |

| Condition: | New |

| Function: | Filling, Wrapping, Sealing |

| Application: | Apparel, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Medical, Textiles |

| Packaging Type: | Bags, Film, Foil, Pouch, Stand-up Pouch |

| Packaging Material: | Plastic, Paper |

| Automatic Grade: | Automatic |

| Driven Type: | Electric |

| Voltage: | 220V |

| Power: | 2.2KW, 220V,50/60HZ,1.1Kw |

| Place of Origin: | Guangdong, China (Mainland) |

| Brand Name: | UMEO |

| Dimension(L*W*H): | L1150*W960*H1780mm |

| Certification: | CE Certification |

| Bag Length: | 20-170mm |

| Bag width: | 15-110mm |

| Width of packing film (Max.): | 240mm |

| Packing speed: | 20-70 bag/min |

| Measuring range: | 50ml (Max.) |

| Roll Dia. of packing film: | 300mm |

| Film material: | Complex film:OPP/CPP,OPP/PE,Al.Film etc. |

| Film thickness: | 40-80um |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Selling Units: | Single item |

| Single volume : | 3 cm 3 |

| Single gross weight: | 320.0 kg |

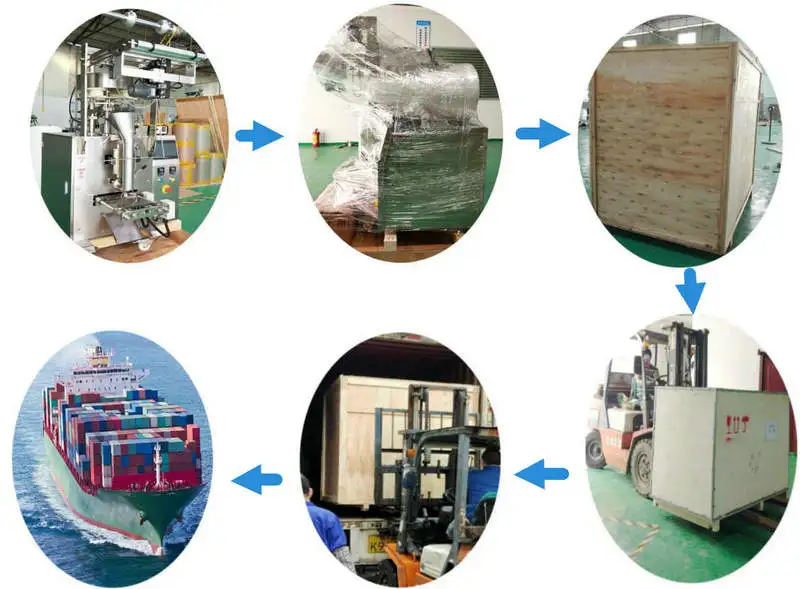

| Package Type: | Inner wrap PE film,external with reinforced non-fumigation plywood case. |

| MOQ: | 1 Sets |

| Price: | US $3300.00 |

Honey packing machine

Feature

1. Imported PLC computer control system,color touch screen,easy operation and much more stable;

2. Seperate pneumatic control and power control with low noise and more stable circuit ;

3. Imported servo pulling film system and imported color sensor,accurate positioning,perfect operation;

4. Multiple automatic alarm protection,reducing the loss furthest;

5. Double belt pulling film to make the packaging bag smooth and

perfect;

6. Enclosed mechanism is used to prevent dust entering effectively.

Specification

Application

honey packing machine is suitable for packing liquid or sauce,such as honey,water,milk,fruit juice,spices,etc.

Bag sample

Pre-sales Service:

Step 1: One on one free project consulation,designing and free cost evaluation.

Step 2: Production line recommendation.

Step 3: Order confirmed.

Medium-sales Services:

Step 4: Deposit in and machine production on.

Step 5: Qualified raw material suppliers ( fabric,solutions,films,stickers etc) introduced.

Step 6: Raw material sample purchased for trial running.

Step 7: Machine inspection,installation and operation training conducted.

Step 8: Wipes production experience provides.

Step 9: Machine settled for standard plywood case packaging.

Step10:Balance received and delivery machine.

After-sales Services:

Step11: Machine transportation.

Step12: Long-distance guidance for installation and operation or engineer available for oversea.

Step13: Life-long machine maintenance service and warranty.

scan following Wechat to talk price directly or mail us by the link

CONTACT US

| BACK TO HOME PAGE > |

|