| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Continuous Casting Machine |

|---|---|

| Place of Origin: | Jiangsu Wuxi China (mainland) |

| Brand Name: | Haijun |

| Model Number: | R4M 2 strand |

| MOQ: | 1 Set |

| Packaging Details: | Container |

| Delivery Time: | 2 month |

| Payment Terms: | T/T , L/C |

| Supply Ability: | 30 strands CCM per year |

| Certification: | ISO 9001 |

| Price: | Negotiable |

| Condition: | New |

| Power(W): | 22kw-1000kw |

| Product name: | Haijun |

| Weight: | 3-10tons |

| After-sales Servise: | Engineers available to service machine |

| delivery date: | 100days |

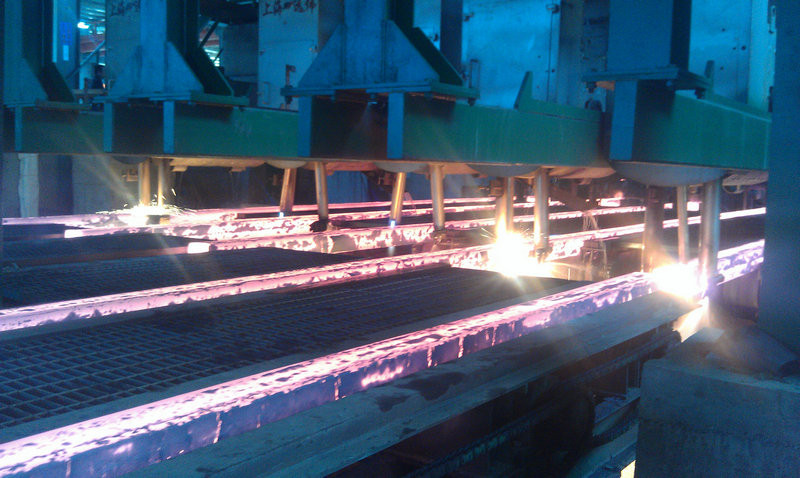

R4M Continuous Casting Machine with Tundish Car , 2 Strand Cast Steel

1. Quick Detail:

radius: R4M

Strand number : 2 strands

with ISO certification

CCM continuous casting machine

We can produce high quality continuous casting machines from 1 to 8 strands with the lowest equipment manufacturing cost.We can design, manufacture the up-to-date billet continuous casting machine in accordance with the user's steelmaking capacity, billet size, steel grades and the user's field conditions.

1. Basic standby technical parameters:

Steel billet casting machine radius | 4m |

Strand quantity | 2 strands |

Ladle support type | Ladle turret,Ladle car,ladle mounts |

Tundish carriage | Semi-portal, cross sliding function |

Casting method | Metering nozzle, open casting |

Secondary cooling | Water cooling , 1 adjusting circuit |

Withdrawal straightening machine | Totally 5 roller, progressive straightening |

Roll table | Chain group centralized drive |

Dummy bar | Rigid, with self-adapting dummy bar head |

Billet cutting | Manual cutting |

Billet conveying | Group centralized live roller table |

Cooling bank type | Simple cooling bed |

2. Technical process description and capacity of steel billet CCM

Induction furnace:

Nominal capacity | 15T |

Tap-to-tap cycle | 60min |

Furnace quantity | 2set |

Production capacity

Working days | 330 days/year |

Average number of daily furnace | 24/day |

Production capacity | 100,000t/year |

3. Casting speed, productivity and strand quantity

R4m radius casting machine can cast steel groups of different specifications, the maximum casting speed

is as follows:

Casting sectional area(mm) | 80×80 | 100×100 | 120×120 |

Casting speed(m/min) | 3.0 | 2.8 | 2.6 |

NO. | Billet size | Casting speed | hourly output (tons) | Daily output 24hour (tons) | Annual output(330days) (tons) |

1 | 80×80 | 3.0m/min | 7.42 | 178 | 58,766 |

2 | 100×100 | 2.8m/min | 10.81 | 259. | 85615 |

3 | 120×120 | 2.6m/min | 15.69 | 377 | 124,266 |

The calculation results is the ideal state of the production, please according to own actual situation of

adjustment.

Steel grade | Casting grade(m/min) | Effective deformation rate(ε) | Allowable deformation rate(εmax) |

Straight carbon steel | 1.8~2.5 | Please refer to the computational table | 0.25 |

Low alloy steel | 1.3~2.0 | Please refer to the computational table | 0.15~0.2 |

4. CCM equipment parts list

No. | Machine name | Weight | Unit | Quantity | |

Ⅰ | Equipment body | ||||

1 | ladle car | 5T×2=10T | set | 2 | |

2 | Tundish carriage | 2T×2=4T | set | 2 | |

3 | Tundish | 1.4T×2=2.8T | pec | 2 | |

4 | Mould 100×100 | 0.53×2=1.06T | set | 2 | |

5 | Mould roller | 0.01×2=0.02T | set | 2 | |

6 | Mould cover | 0.1T×2=0.2T | set | 2 | |

7 | Mould oscillator | 1.5T×2=3T | set | 2 | |

8 | Secondary cooling spray tube | 0.5T×2=1T | set | 2 | |

9 | Secondary cooling guide part roll | 0.5T×2=1T | set | 2 | |

10 | Secondary cooling overboard steam drain system | 1.1T | set | 1 | |

11 | Withdrawal and straightening machine | 6T×2=12T | set | 2 | |

12 | Dummy bar | 0.9T×2=1.8T | set | 2 | |

13 | Dummy bar storage device | 0.7T×2=1.4T | set | 2 | |

14 | Roll table before cutting | 1.5T×2=3T | set | 2 | |

15 | Simple cooling bed | 1.2T | set | 1 | |

16 | Billet head and cut off slag collection system | 0.5T | set | 1 | |

17 | Roll road | 1.5T×2=3T | set | 2 | |

18 | Billet out-going roller | 1.5×2=3T | set | 3 | |

19 | Steel lateral shifting machine | 3T | set | 1 | |

20 | Flame cutting machine | 1T×2=2T | set | 2 | |

21 | Hydraulic station system | 1.6T | set | 1 | |

22 | Water cooling station | 1.6T | set | 1 | |

23 | Steel platform | 45T | 1 | ||

Ⅱ | Three Electric System | ||||

1 | Electric control equipment | set | 1 | ||

2 | Scene meter | set | 1 | ||

3 | Computer system | set | 1 | ||

Ⅲ | Installation material | ||||

1 | Electric instrument system material | 1T | Set | 1 | |

2 | Hydraulic piping system material | 1T | Set | 1 | |

3 | Cooling water system material | 1T | Set | 1 | |

Ⅳ | Offline equipment | ||||

1 | Mould repairtable | Set | 1 | ||

2 | Mould support stand | Set | 1 | ||

3 | Pair arc template | Pair | 2 | ||

|