| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Double Layer Roll Forming Machine |

|---|---|

| Brand Name: | XINGHE |

| Model Number: | XH836/1000 |

| Certification: | BV,SGS, CE,ISO9001 |

| Place of Origin: | Botou,Hebei Province |

| MOQ: | 1 Set |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 30 SETS / MONTH |

| Delivery Time: | 30 Working days |

| Packaging Details: | Naked and fixed into container |

| Condition: | New |

| Type: | Tile Forming Machine |

| Tile type: | Colored Steel / PPGI / Galvanized Steel Coil |

| Power: | 7.5+5.5kw |

| Voltage: | 380V 60HZ or at your requirement |

| Dimension: | 8900*1300*1500mm |

| Machine Weight: | 8.0Tons |

| Warrenty: | 12 months warrenty and long-life after-sale service |

| After-sales Service: | Engineers available to service machinery |

| Middle plate thickness: | 16mm |

| Control System:: | PLC(imported Brand) |

| Roller Material:: | 45#steel Chrome Plated |

| Shaft Material:: | 5mm Chrome Coated |

| PLC Automatic Zinc Roofing Roll Forming Machine/Corrugated Roof Sheet Making Machine/ Roof Panel For: | 75mm |

| Cutting Blade Material: | Cr 12 High Grade Steel |

Appearance size: 8900mm*1550mm*1510mm

Width range: 1220mm

Thickness range: 0.25-1.2mm

Inner diameter range: 500mm

Speed of product: 20-25 m/min

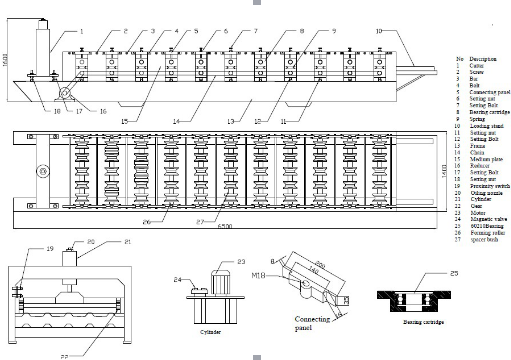

2. Processes and components

Processes: Man-made uncoiler—Roll forming machine—PLC system-Hydraulic system-Blade—Receiving table

Flow chart:

3. Components of line:

| No. | Name | Unit | Qty |

| 1 | Man-made uncoiler | set | 1 |

| 2 | Main machine for roll forming | set | 1 |

| 3 | Control system | set | 1 |

| 4 | Hydraulic system | set | 1 |

| 5 | Blade | set | 1 |

| 6 | Receiving table | set | 1 |

4. Function and structure:

Man-made uncoiler

Application and technical parameter :

Inner diameter:500mm

Outer diameter:1100mm

Width:1000 mm

Loading weight:less 5 T

5. Main machine for roll forming

Application and technical parameter:

Pass:16/18 passes

Shaft diameter:75mm

Roller material:45 steel(Cr coating)

Total power:7.5+5.5KW

6. Control system:

Function and operation:Control the starting ,operation and stopping of the complete line, including distribution section, operation table, counting instrument. Use PLC to control, set and adjust the length. Both man-made and auto operations: on the man-made condition, each equipment can operated by switch; on the auto condition, only circulating stop and rapid stop switch.

Install chart:

7. Hydraulic system

Function: apply power for cutting machine

8.Blade

Function and structure: cutting the forming sheet

Application and technical parameter:Blade material: Cr12 and Harding treatment

Max thickness: 0.3-1.2mm

|