| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Zirconia Ceramic Parts |

|---|---|

| Brand Name: | Mingrui |

| Model Number: | Customized |

| Certification: | ISO9001:2015,,CE |

| Place of Origin: | China,Guangdong |

| MOQ: | 1 pieces |

| Price: | negotiable |

| Payment Terms: | Western Union, L/C, T/T, D/P, D/A, MoneyGram |

| Supply Ability: | 500 pieces week |

| Delivery Time: | 15-25 working days after the order confirmed |

| Packaging Details: | Packed in PP bags or sponge tray, then put in standard export carton packing. |

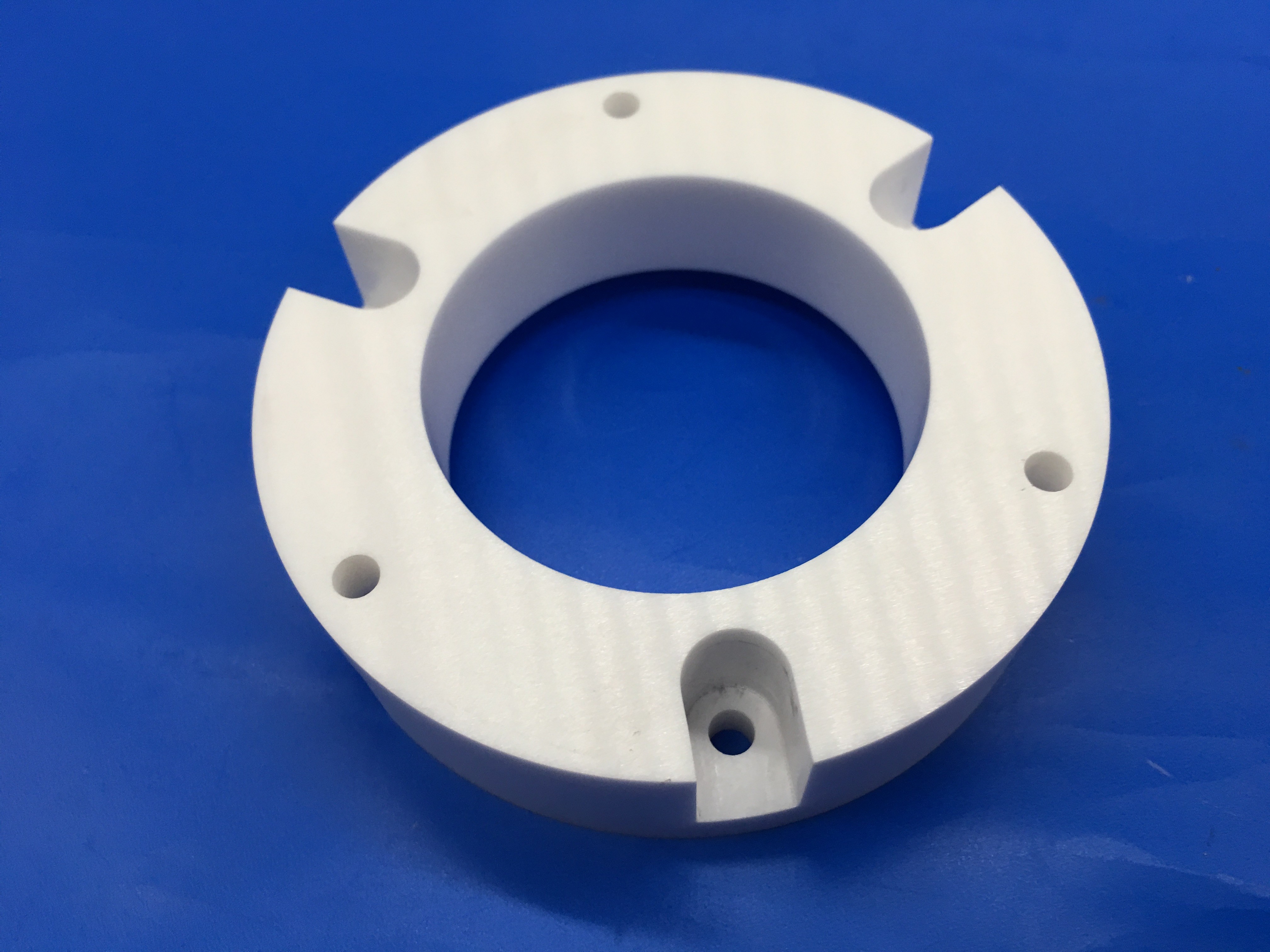

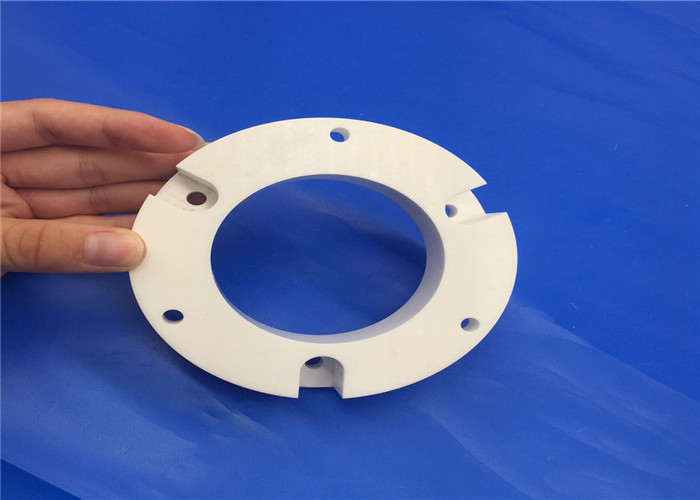

| Key words: | Alumina ceramic flange |

| Tolerance: | 0.001mm |

| Forming way: | CNC machining |

| Characteristic: | Smooth Surface |

| Material: | Alumina |

| Flexural Strength: | 280 - 300 Mpa |

| Max. Working: | 00 - 1800 °C |

| Electrical Insulation: | Excellent |

| Thermal Shock: | 180 - 220 T(°C) |

| Water Absorption: | 0% |

High Strength Excellent Insulating Insulated Alumina Ceramic Flange

Specification:

*Good thermal conductivity

*Good strength and hardness

*Good resistance to wear and corrosion

*Temperature resistance up to 1700°C

Features of Alumina Ceramic Flange :

1).High Mechanical Strength

2).High Thermal Conductivity

3).High Spalling Resistance

4).High Softening Temperature

5).Excellent Insulativity

6).Etching Resistance

Appplication

1) Power Control Circuits

2) Semiconductor Power Control Modules

3) Semiconductor Refrigerators

4) Intelligent Power Assemblies

5) Power Hybrids

6) Solid-state Relays

7) Electronic Devices for Automobile

8) Solar Cell Board

Ceramic Properties

| General Characteristics of Materials: | ||||

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium | High | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

| Oxidation Resistance | Medium to High | low | low | / |

| Machinability | Medium | low | Medium | / |

Product Description

Available shapes:

Our Alumina Ceramic products can be made into different shapes like ceramic rods, ceramic bars, ceramic tubes/tubings, ceramic bushings/ceramic bushing, ceramic sleeves, ceramic seal rings, ceramic washers, ceramic ball valves, ceramic pistons, ceramic disks, ceramic plates/sheets/substrates or other customized shapes.

According to actual application and customer's requirement, the purities vary from 95%-99.7% and the forming methods will be different. The forming methods applied in our plant include dry pressing, isostatic pressing, injection moulding, extrusion moulding. With experienced engineers and talented workers, we are confident to offer high quality, high precision, complex components for customers worldwide.

Production process:

More photos :

Factory Shows

1. Are you a manufacturer ?

Yes we are a ceramic manufacturer . We proceed with the whole

process start from Powder material to forming , sintering ,

machining, marking , inspection , packing , we do the whole process

.

2.Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is up to

the product complexity .

3.What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but

paypal and western union only for small -sum payment.

|