| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | PCB Depaneling Machine |

|---|---|

| Brand Name: | YES |

| Model Number: | YES-9 |

| Certification: | CE ISO |

| Place of Origin: | China |

| MOQ: | 1 SET |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 300 sets per month |

| Delivery Time: | 1 day |

| Packaging Details: | Each set be packed in plywood case |

| PCB Separator Blade: | 32 blades |

| Separation Speed: | Adjustable |

| Efficiency: | 5-9 pcs one time |

| Warranty: | one year |

| Lead time: | one day |

| Application: | LED Lighting |

T8 T5 V Cut PCB Depaneling Machine Multi Slitters For LED Lighting

Assembly

PCB Depaneling Machine Similar cab maestro 5l competitive feature:

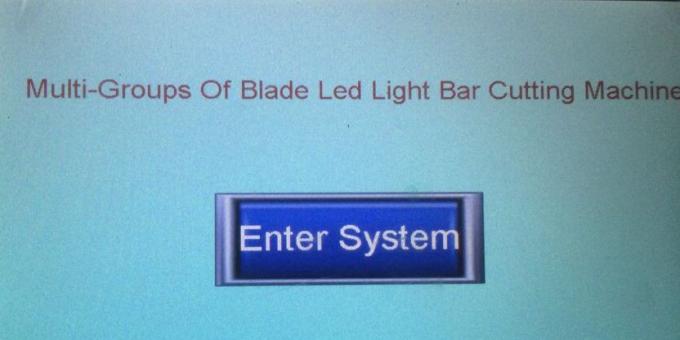

1. The machine adopts the computer screen control with a counting

device , which you can use to preset the processing production .

And the space of cutting tool is visible on the screen .

2. It can cut many boards with multiple sets of knives work at the

same time

3. The knife flywheel is adjustable as a whole from 0 to 5mm

4. The distance between knives is regulable as well , applying to

pcb with width from 15mm to 20mm .

5. The blade is made of imported high speed steel material , which

is durable and have a long service life

6. It is convenient to adjust the cutting speed through rotary knob

.

7. No limits of the cutting length

.

8. Thickness range of pcb : 0.2-5.0mm

9. With a conveyor belt line , the separated pcb can be send out

directly to reduce pick- and-place .

10. The machine adopts multiple blade to separate boards with

simple operation and high efficiency

Specification OF PCB Cutting Machine :

| Maximum board length : | unlimited |

| Board thickness : | 0.6-5.0mm |

| Plate feeding speed : | 300-500mm/s |

| Blade material : | SKD11 |

| Working temperature : | 10-35℃ |

| Storage temperature : | -20-50℃ |

| Voltage : | 220 /110 V |

| Dimension : | 2200 mm*630 mm*1150mm |

Why Clients Buy Our PCB Separator Model YES-9

1. Currently in the PCB Separator Market, it is the only machine

that can separate PCB Panel into Pieces at a time and guarantee the

aluminum plate without deformation after cutting .

2. With unique cutting method, the circuit board is cut by 32

blades. It is a group composed of one upper and one lower blade,

and is also a cutting unit.

There are 18 groups. because each cutting volume is small, the

stress produced during the cutting progress declined by more than

50% compared with the traditional cut off at a time.

Thus the edge of the board and its surface are very smooth without

warping .

LCD control PCB Cutting Machine :

Why you should choose our pcb separator service

1. Engineers available to service machinery oversea. |

2. Mature technique & forerunner to process makes high quality

machinery. |

3. One year warranty for the machines except accessories. b router

machine |

Our mission:

Ongoing PCB industry PCB separator technological innovation, to

create greater value, allowing customers to success

Our Vision:

PCB industry to become the world's leading solution providers PCB

separator. pcb router machine

Customers FAQ About PCB Separator YES-9:

1. Q:Do you have any certification for this machine?

A:YES,We have CE ISO FCC ROHS etc.

2. Q:What is warranty of the machine?

A:1 year.

3. Q:How do you pack the machine?

A:We fix the machine on the plywood base with screws to ensure safe

transportation.

4. Q:What is life time of machine blades?

A:About 6-12 months.

5. Q:What is material of blades?

A:Japan high speed steel SKH-9

6. Q:Can the blades be sharpened?

A:Yes, they could be re-sharpened for 2-3 times.

7. Q:How do you offer oversea service?

A:We could send engineer to do installation and training for client

if needs.

8. Q:Can we see your machine in our country?

A:Yes, we would like to offer contact details of our clients who

are using our machines.

|