| Sign In | Join Free | My chinacomputerparts.com |

|

| Sign In | Join Free | My chinacomputerparts.com |

|

| Categories | Roll Forming Equipment |

|---|---|

| Brand Name: | SUSSMAN |

| Model Number: | SS-VY |

| Certification: | CE, SGS, ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 60-90 working days after payment |

| Packaging Details: | Standard package with film, plastic and steel wire. (or customized) |

| Material: | Galvanized steel sheet |

| material thickness: | 1.5-2mm |

| Forming stations: | 16 stations |

| Roller material: | 45# Steel with quenching 60mm shaft |

| Dirve system: | Gearbox drive |

| Power supply: | 380V, 50Hz, 3Phase |

| Main Motor Power: | 7.5 KW |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

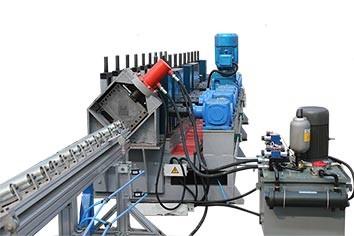

Vineyard Post Making Machine

Technical Parameter

Item NO. | Description | Offered Specification |

1.0 | Roll forming machine | |

1.1 | Rolling speed | up to 20m/min(not include cutting time) |

1.2 | Rolling thickness | 1.5-2mm |

1.3 | Raw material | Galvanized steel sheet |

1.4 | dimension | 20000×1200×1200(mm) |

1.5 | Effective width | 200mm |

1.6 | Roller stations | 16 stations |

1.7 | Roller material | 45# steel, coated with chrome, Quenching |

1.8 | Shaft diameter | Φ70mm ,material is 45# forge steel |

1.9 | Transmission | Gearbox |

1.10 | Material of chain | 45# forged steel with frequency quenching, 12A |

1.11 | Material of cutting | Cr12Mov with quench HRC58-62° |

1.12 | Cutting Tolerance | 6m+-1.5mm |

Main Components

S.N | Equipment Name | Quantity |

1 | 3T hydraulic De-coiler | 1 set |

2 | Leveling device 200mm | 1 set |

3 | Servo feeding device 200mm | 1 unit |

4 | Press machineJH21-63 | 1 unit |

5 | Main roll forming machine | 1 set |

6 | Cutting holder | 1 set |

7 | Hydraulic station | 1 set |

8 | Control system ( including control box) | 1 set |

9 | Out tables | 2 units |

10 | Spare parts | 1 package |

16 | Cutting dies | 1 set |

17 | Punching die set | 1 set |

Working Flow of Roll Forming Machine

Decoiler----feedingwithguide---Punching----Rollforming----Cutting----Products collecting

Profile of product

Loading pictures

After-sale Serive

- The seller take responsibility to installation and commissioning

of the equipment and free training. After machine arrive the

destination, by the request of the buyer , the seller will provide

1 technical engineer to guide installation and training , and the

buyer should give the technical person with full cooperated.

- Installation period: about 5 days after the complete preparation

by the buyer such as the foundation and all necessary accessories.

- Training time: 5 days.

- Before departure of the engineers from seller, the buyer should

pay for installation and commissioning fee 100$/day to the point

account of the seller. The two-way ticket,visa, food, hotel , the

translator and insurance are all should provide by buyer with full

responsibility.

-The seller supply technical data (including forming mould drawing,

electrical elements drawing and equipment drawing etc.)

Company Profile

Sussman Machinery manufacturing Co., Ltd. is specialized in building materials of light steel structure. Since the factory founded 10 years before, it always designs and produces various type profile

of roll forming machine.

The main products of factory is Roller shutter door, PU sandwish panel line, pre-painted steel forming machine, Racking roll forming machine, the cable tray roll forming machine, Glazed Tile forming machine, Automatical C/Z Purlin forming machine, Floor Deck forming machine, Guardrail forming machine, Down

Pipe forming machine, the whole carriage plate for car beam unit, Steel storage unit, etc. The products

are widely used in warehouse, factory buildings, supermarket, Nursing homes, villas and other

construction projects, Our factory can meet the construction enterprises, automobile industry, Iron and

steel production enterprises' growing demands.

Sussman machinery is located in Wuxi city, Jiangsu province which is close to Shanghai, It's about half an hour's journey. We enojoy the convenient transportation and advantageous location which supply good business opportunities for the buyers home and abroad.

|